Garry Hallam

-

Posts

62 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Garry Hallam

-

-

Hey Guys

Anybody Flown their Pioneer yet. Mine has been gathering Dust since I made it. I am going to sell it now as I need the Space. What would be a fair price with servo's installed?

Garry

-

Thanks for the Suggestion Alistair, However I thought of a more permanent solution by making a thin Brass plate stopper which sits behind the Hub with a hole that goes over the shaft. It is kept in place radially by the Spinner. In the event of a bad landing it bends back again to its originl position. the extra weight is only 3.8 gram - which is nothing to speak of really.

I have included a photo to show it more clearly.

Garry -

Well, My 8.4v 3300mah Battery & Castle Creations Phoenix 35p Speed controller arrived yesterday so I set them up as well as altering the Timing on the Motor. Everything seems great swinging the 12x7 Folding Prop and I was surprised at the low current draw at only 12.8 Amps full throttle, Just need to tidy a few things up now and will be ready for the Maiden Flight.

I am however concerned that when the Prop folds back it can get locked in place by the Wind Band dowels. No Problem at take off as they can be pushed out before starting...however, if it does this during a flight at throtle down then there will be a definate problem! Anybody have any Idea's on overcoming this?

Garry

-

RE: The maiden Flights, I need to check for any twisting in the Wings and ailerons yet and adjust as neccasary. I do know that the ailerons are definately slightly twisted owing to their very light construction.

Incidentally it comes in at 1400gram weight, as chris's did, despite the addition of the gearbox. I have ordered the same 3300mah battery, just hope it fits now!

garry -

Well I finally finished off the Pogostick, I am just awaiting delivery of the Battery & Speed controller now. Here are some Pictures of her.

-

No, I hadn't seen them David, but I'll make my way there now - Thanks for that!

garry -

I figured it out now regarding the 5 Braces! They are top & Bottom of the Spars + the Leading Edge. A side Section on the Drawing would be nice.

garry -

Has anybody else built this Model. I am at the Stage of completing the Wings and the Plan shows 3 Braces, yet the Magazine article refers to 5 of them?

Anybody?

-

Alastair

That was the very article I was refering to! Everything is clear now, I thought the modification actually reversed the rotation without needing to reverse the Polarity. Even at the lower end of the expected increase in RPM will bring it up to 9500 RPM which would seen Ideal. Just wish I had a RPM counter to check Before and after!

Hell,I may even Put Ball race bearings in, as he describes while I'm doing it!

Thanks for your Help

Regards

Garry -

Well I got the Gearbox Made with a ratio of 2.43:1 to begin with. The Graupner speed 600 8.4v 21000 rpm race motor arrived today and should give 8641rpm at the prop and I will try a 12x7 Folding Prop.

Problem is that the Motor needs reversing as it is a simple 2 Gear gearbox. I was just going to reverse the polarity of the Motor as I have done in the Past, but I came across an article on the web that described making Physical modifications to do the Job (Basically involves moving the Motor Back Plate around by about 10 degrees)

Anybody know what the Pro's and cons of doing it either way?

Any help appreciated

Garry -

Alistair

Thanks for that. In fact the Gearbox is one I will be making myself as I have done previously and has interchangable Pinnions for different ratios.

Will have to check out the Prices on those Props.

Garry

-

Back to the Newsagents for you then I guess?

Watch out for that guy on the train carrying a pogostick :) -

Well No replys! having done some research I am going to try a 600 Motor with a 2.5:1 Gearbox and the 11x7 folding Prop.

I may use lipo's to reduce the added weight of the Motor & Gearbox. -

Hi, This looks like a great electric trainer and a good size to learn with as opposed to the usually smaller Electrics. I would like to build it, however, The Brushless setup is a little expensive for me right now!

Is there a brushed motor that could be used instead?

garry -

Hi Tom

Yeah absolutely fine by me. In fact I hoped you'd soon include this. I see there is an image tag now! Brill..

garry -

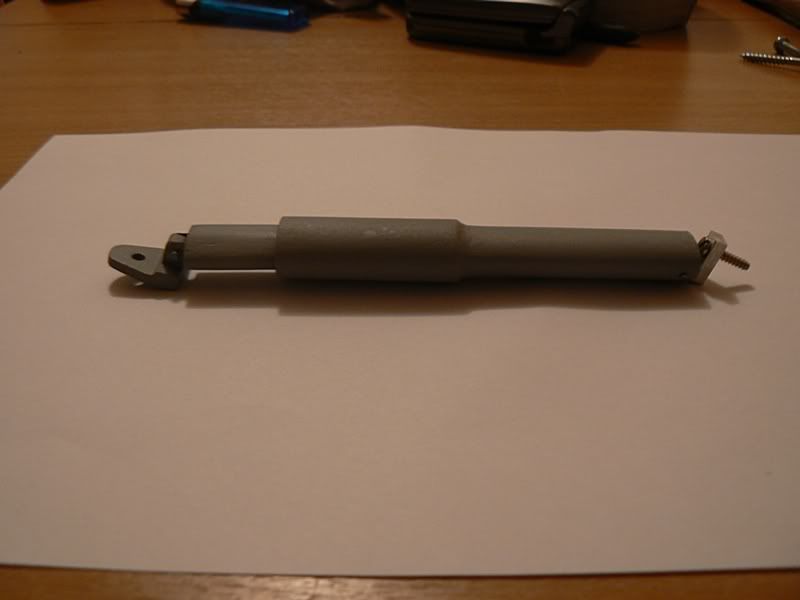

A side view

-

Primed and ready for the top coat

-

Full assembly prior to glueing the Cover

-

The Lower Leg Assembly

-

A stanley blade is my tool of choice too. I work out the width required, mark it out centrally to the blade and then place it in the vice at the lines and use a block of wood and a hammer to snap at the line. cover with a cloth to prevent injury from flying blades! I then work out the height it needs to be off the workboard surface (centre of the piece to be slotted minus half the blade thickness) make a wooden base and glue and clamp the blade making a sort of chisel that is simply pushed in whilst wriggling side to side.

Hold a piece of wood flat on top of the piece being slotted to stop it swelling too much. You could incidentally follow on with a similar but blunted tool afterwards for an even more accurate result. then after inserting the hinges sand the high spots level. Perfect everytime... -

Hey Steve I've built a couple of Guitars also. I used to frequent luthierforum.com

Small world hey..

garry -

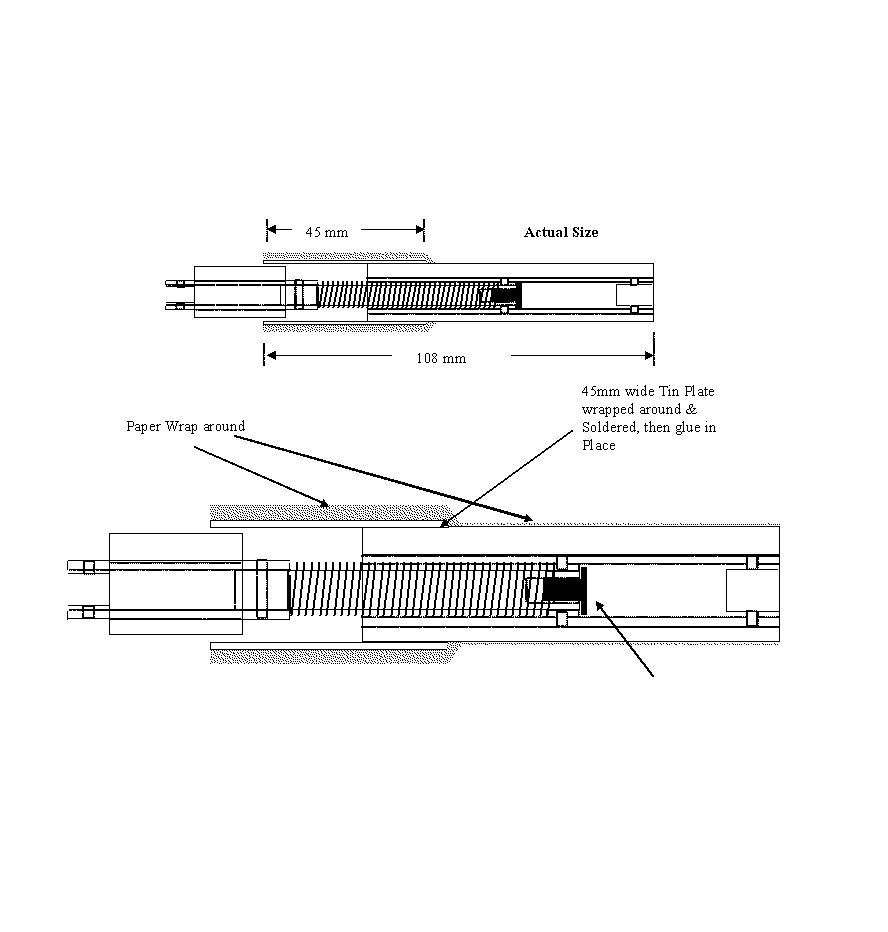

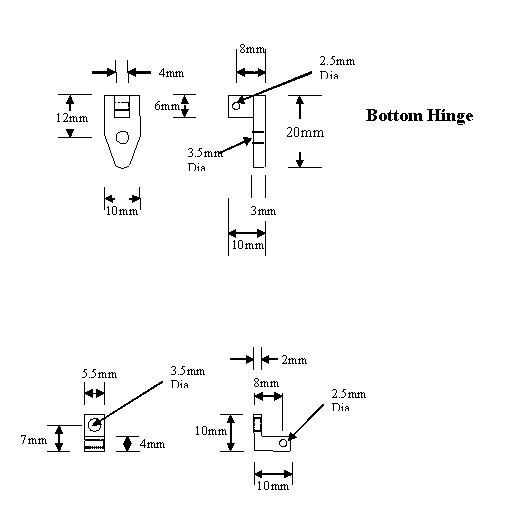

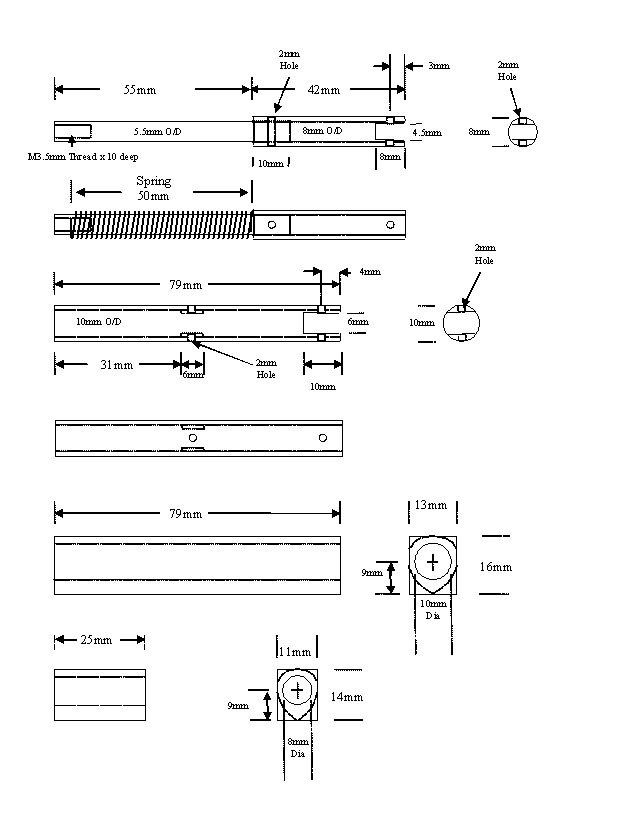

In order to view these images properly, right click and select save as. You will be able to zoom in on your Pc Picture viewer and print out.

regards

Garr

(ADMIN EDIT: you can now also simply click on the image for a larger version)

-

-

Scottish Aviation Pioneer

in RCM&E Plan Builders

Posted

No I not flying now! Selling up.

garry