TigerOC

-

Posts

333 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by TigerOC

-

-

Regular and favourite place of flyers from Okehampton. Countisbury Common. Park in the public parking just past the Bluebells pub(?) and walk over to the radiomast on the hill. We fly to the left of the mast. Flies W - WNW. Fantastic areas behind you to land.

Rob

-

1

1

-

-

37 minutes ago, Andy Stephenson said:

I use Easy Composites EL2 epoxy. Using digital kitchen scales, I found I had to use too much to get an accurate mix so I invested in a cheap ebay micro balance to accurately weigh out 10g at a time. I also now use Peep-ply which increases the expense but does reduce the amount of epoxy remaining on the surface, it leaves a much more consistent surface finish and holds down the glass to eliminate voids. Also it has the advantage that only one coat of epoxy is needed.

Use the same process for sheeted foam core wings. I then put them in clothing vacuum bags and pull a vacuum and leave for 24 hours. This produces great results.

-

1

1

-

-

I can highly recommend this; https://www.easycomposites.co.uk/el2-epoxy-laminating-resin

It is odourless and good value for money. Recommend measuring by weight.

If this is still too expensive then Wilko sell an excellent Water based Polyurethane quick dry varnish which I have found to be as good as the expensive diamond hard brands.

-

1

1

-

-

May I also add that we have a number of school age children in our club and most are involved in building models. Suddenly many aspects of their education become very apparent. Recently we applied to a local charity for a grant to buy a ride-on mower. They were amazed at the social and educational aspects of our club and we were awarded the grant.

Rob

-

2

2

-

-

At our monthly aerotows we regularly have 2 acting as tugs and one has a DA 50 and the other a DLE 55. They certainly don't lack power?

-

I build foam core wings and have in the past used the wbp method. A guy in the club who worked in composites advised looking at peel ply. The last set of wings I have completed I used a new technique.

Preparation; cut the cloth and peel ply before starting. Prepare an appropriate size home vacuum storage bag. Ensure the surface is dust free. Have disposable/vinyl/latex gloves to hand.

Lay the glass cloth and apply epoxy laminating resin from the centre and squeeze out with a soft squeegee working outwards. I use a piece of depron. When done, apply the peel ply and go over the surface with your hands to make sure the surface is smooth and eliminate any creases or air bubbles.

Now place in the vacuum bag and pull a vacuum. Leave it for several hours. Open the bag and remove. Pull the peel ply and you will have a stippled super strong surface because all excess resin has been drawn out of the surface into the peel ply. It also cures much faster than just coating the surface with resin.

This provides a stippled surface with a nice sheen. It can be sanded to remove the stipples. The experts say this method is as close to vacuum bagging that you can get with simple tools.

-

Technically the engine will run in any attitude. DLE use Walbro/equivalent carbs which are pumped carbs and no float chamber which would rely on gravity. The pump mechanism is driven by the pulse of the engine. Technically it should also operate in any orientation. There is a small hole on the top of the pump mechanism that requires atmospheric pressure and in some situations with strange airflow eddies in a cowl this can cause problems.

In short; no reason why it shouldn't work.

Some detailed info on how these carbs work;

Edited By TigerOC on 03/09/2020 22:01:25

-

Details of the trials in a new era of automated/remote aircraft delivery systems;

-

I have been building balsa sheeted foam core wings for a few years. Most are smaller 1.5m glider wings.

These are sheeted with 1/32 hard balsa. The process I use is to coat the over size balsa sheet with Lumberjack 30 minute polyurethane glue spread thin with a card and spray water lightly on the foam core. The wing is sheeted and then placed back into the wing bed and then into a suitably sized vacuum storage bag. This is then weighted on a very level surface and the bag vacuumed. This is left for an hour. My experience is the sheeting is very well bonded and I have not yet had a failure under load. On bigger wings I use 1/16th hard balsa.

I have 32" bow and power it with a 4S lipo which works really well. I have a switch on the bow.

-

The notes that come with 2.3.2 indicate an upgrade to the new ACCESS protocol. The protocol encrypts transmission from the Tx to the Rx. The Rx's would require flashing with the new firmware to be able to handle the ACCESS protocol.

-

Posted by Peter Christy on 25/07/2019 14:01:54:

I see that the new Minister for Transport is Grant Shapps. IIRC he is a keen aviation enthusiast, holds a PPL and has his own 'plane. He has been a staunch defender of General Aviation against intrusive legislation, and at the back of my mind is that he has also been a friend of model flying. Does anyone else remember this?

Anyway, now that we have an aviation enthusiast in the job, maybe - just maybe - common sense will prevail!

--

Pete

In fact as Chairman of that Committee he actually wrote to the Minister requesting justification for the inclusion of the Model Flying community in this draconian system. His letter was published by the BMFA but we have not seen the response. Probably the standard response that everyone else got; Don't confuse me with facts as my mind is made up.

Rob

-

A point I have made to my MP (Leader of the House) is something that has never been mentioned at all; Local Bye laws.

When i started flying some 8 years back I took the trouble to look at our local Bye laws and they ban the flying of all model aircraft above 100g within the borough. I live close to Dartmoor National Park and their Bye Laws are that all powered models are banned but they welcome model gliders.

I am sure that this is not unique to our town.

Rob

Edited By TigerOC on 19/07/2019 22:29:03

-

Posted by Martin Harris on 11/06/2019 17:53:21:

Obviously not the case then and I wasn't inferring any lack of competence on your part - I thought you were talking about airframe checks - but some plug caps can give the impression they are connected while leaving a spark gap, sometimes to the detriment of the ignition system which can suffer permanent damage.

The cdi units used on the DLE have a split ring on the spark plug cap that expands over the plug hexagonal section when fitted correctly. If fitted incorrectly it falls off. They are known to be a pain to lever off when on.

-

Posted by Martin Harris on 10/06/2019 22:33:41:

Let's hope it wasn't just a loosened plug cap!

??????? With respect some of us do have brains. I did say I did some extensive testing.

-

I have had a similar experience recently. I have a model with an RB10 redundancy system and 2 X8R's. Separate batteries for RX's and ignition. The model is powered with a DLE 30 and standard ignition. I having been flying it for 6 months without issue. I had a mishap on take off and put it in nose first breaking the prop. After a going through all the checks and replacing the prop I took it out to the field, started the engine and it immediately started going rapidly in and out of fail safe mode. The conclusion was that the either the cdi or the ignition lead had been damaged.

Have now replaced the ignition system with a HK ignition system and the engine starts better and runs better than with the original system and we have had no further issues with interference. Conclusion there must have been stray spark issues causing the problems. Never experienced total lockout.

-

-

We did a modification to the deck because we are in sheep pasture. The deck is a twin blade so we added 2 deck wash attachments.

We tapped into the water supply for the water troughs and the deck is always sparkling clean.

As with all things mechanical; regular care and servicing keeps them running smoothly. The engine hasn't used a drop of oil in the 2 years so the cylinder and rings must be pretty good. Service from Cheap Mowers has been very good.

The tracker we used is for motor bikes and powered with a lithium battery which has a 4 day life and communicates via mobile phone card and programmed via text message. We had to install a solar panel because the battery in the mower was unable to support the draw during the winter months.

The field is way out in the sticks and we don't suffer the same petty crime found in larger urban areas.

Rob

Edited By TigerOC on 20/04/2019 09:52:01

-

We bought one of these for our club 2 years ago and it is very good;

Lawn-King-DL96T-38in-Cut-Lawn-Tractor

Our main short area is 1200 sq m with outer area of slightly longer grass. Shortest cut is 38mm. Most of the small models cope fine with grass at this length. Takes about an hour to mow the area. We have fitted a GPS tracker.

Edited By TigerOC on 19/04/2019 22:18:52

-

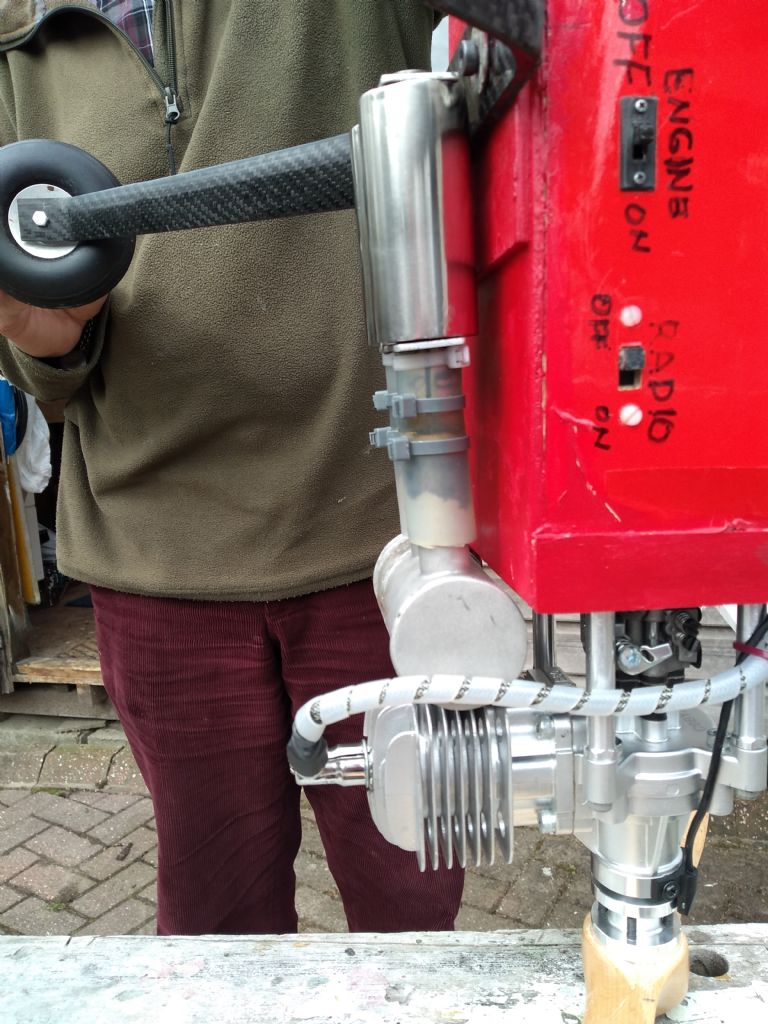

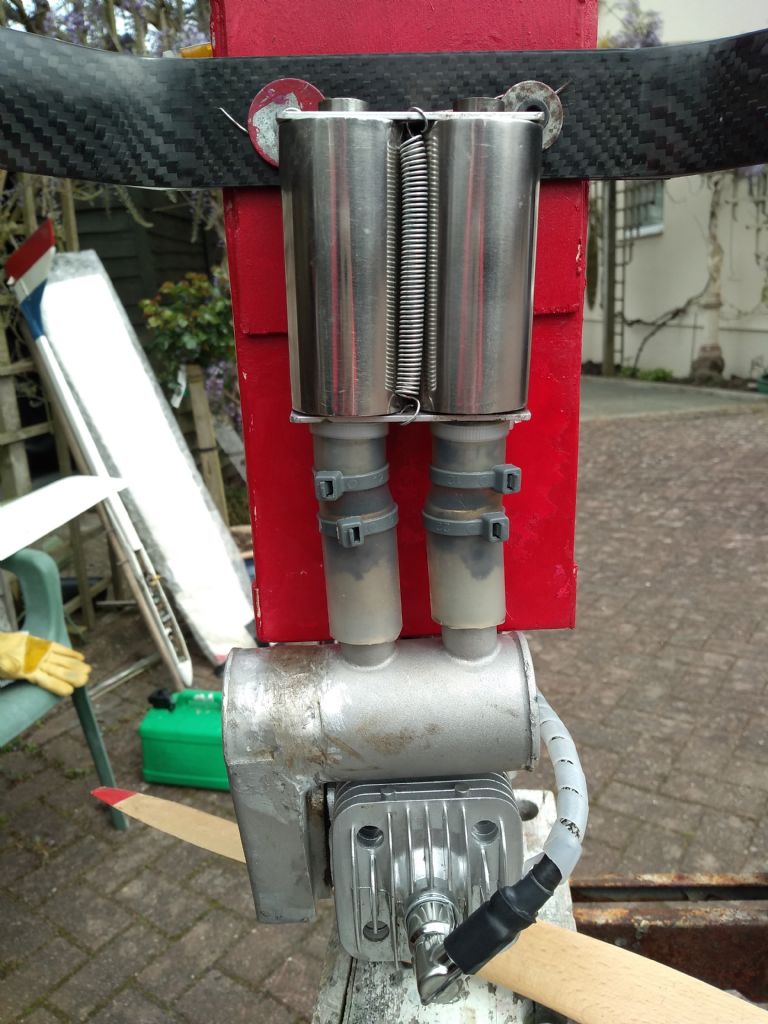

I don't have a picture of the finished article after the welder turned the exhausts from the Pitts but here is picture of the test rig;

Note the Pitts exhausts have just been cut shorter. There is a barrel chamber welded to the manifold section. The welder cut the barrel where it joins the manifold and then turned the barrel 90 degrees so the exhaust is discharging back under the fuselage. The 2 canisters were then connected using the silicone pipe. The outlets from the Pitts exhaust are 16mm diameter so they matched the inlet of the canisters quite well.

I made up another Al bracket that tucks up under the fuselage and this uses springs to reduce the stress forces from the vibration on the canisters.

-

I run a DLE 30 and had to get it under 82db.

Bought a Pitts muffler from HK and got a welder to turn the discharge cylinder and pipes through 90 degrees so it discharged back instead of down. Bought 2 of these;

Connected them via the supplied connector pipes and suspended them with a sprung bracket.

The test results were 79db front and 75db sides and 77db back at 7m. The tone of the engine is much deeper and less raucous. All at low cost. The stainless steel mufflers add are heavier than Al but the model is very over powered anyway.

Rob

-

Regarding DLE silencing;

Buddy and I have recently used a DLE 30 in a Ultra Stik type build and noise was a problem registering 89db. We solved it quite cheaply. Bought a Pitts type exhaust from HK at £30 and had a local welder cut and rotate the outlet pipes through 90 degrees so they were facing back along the bottom of the fuselage.

We then bought 2 of these s/steel mufflers;

These are essentially flow through mufflers.

Connected them with 16mm ID silicone tubing. Noise now 75db side and 78db front. It sounds really nice and it looks good too.

Rob

Edited By TigerOC on 06/11/2018 21:59:14

-

Found the answer. The member had copied the model to set up a new model not realising the RX number transfer was important. So both models had the same RX number. An important lesson learned.

Rob

-

I have asked the person concerned to check whether the receiver numbers in the profile are different or the same.

Personally I have been very fastidious about ensuring this is the case.

-

Am aware of that Dickw. Have a glider tug using an RB10 and 2 RX's bound in one model BUT they are specifically bound to that single model. The question here is 2 separate RX's (X8R) that are bound as separate models.

Damn those Brit Typhoons..

in All Things Model Flying

Posted

Our club, also near Dartmoor National Park, has frequent military aviation visits at low level. After a January airprox we were advised by both RAF and BMFA to get a permanent NOTAM. This works.

The RAF explained that pilots pre-plan their sorties and NOTAMS are incorporated in the flight plans.