-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Birgir

-

-

Thanks Donald, of course, it is the square area that counts

-

Dear friends

Browsing the net about Bleriot XI rc model, I came across a text on Mick Reeves webpage that describes a 1/3 scale Bleriot XI model.

The main facts from that text is:

- Wingspan: 115”

- Weight of nose ballast: 4 kg

- Total weight of model: 14 kg

- The model flew.

My question is:

Can I downsize this information to my 60” wingspan model using the rate 60/115 assuming that my model could take 52% of the weight i.e. 7,3 kg (incl. 2 kg of ballast)?At present it looks like my model will be 2.6 kg incl. 0.55 kg of ballast, a lot less than the calculation above.

Birgir

-

Thanks for the advice.

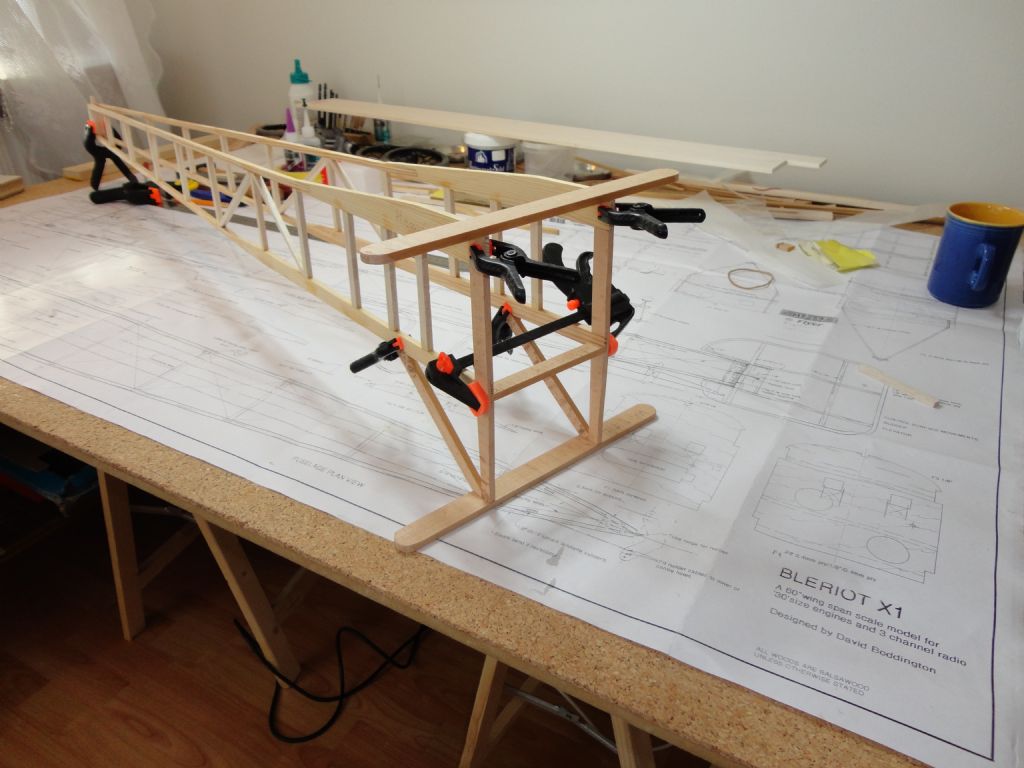

The building is coming along nicely, enjoying every step of the way

http://flugmodel.weebly.com/bleriot-xi.html

Birgir

Edited By Birgir on 30/10/2015 19:45:45

Edited By Birgir on 30/10/2015 19:46:48

-

Thanks for the advice

Im not sure that I can buy balsaloc in Iceland, but Im in Glasgow for today. Do you know of any modelshop in central Glasgow? -

-

Hi

This is a very interesting discussion and there are many good advice here.

John, if your model, without engine and battery, is 3.63 kilos it could be about 4 kilos dry weight with engine and battery.

My model is 1.55 kilos without wings and covering. If I use the ratio between wingspan.e. 60” to 90” I must keep mine below 2.66 kilos. Hopefully that gives me some margin for lead.

Is this way of thinking logical?

B

-

Hi John

What an exciting project. I agree that a project like that should be enjoyed slowly, like eating a good dinner.

A lot of questions come into my mind. Do you know the weight of the airframe? Do you know if it was flown a lot with the 61 engine? Was it powerful enough?

And last but not least; have you tested where the CoG is?

B

PS. To Donald Fry - I agree

-

-

Thanks Simon

I found a thread at rcgroups.com, **LINK** that is very enlightening.

The CoG in my model is at present, i.e. without wings and covering (and lead), at 48%. So, perhaps I can do with a little less lead than I feared.

B.

P.S Yes, the wheels are my own design http://flugmodel.weebly.com/teinahjoacutel.html

Edited By Birgir on 11/10/2015 22:54:24

-

Hi everyone

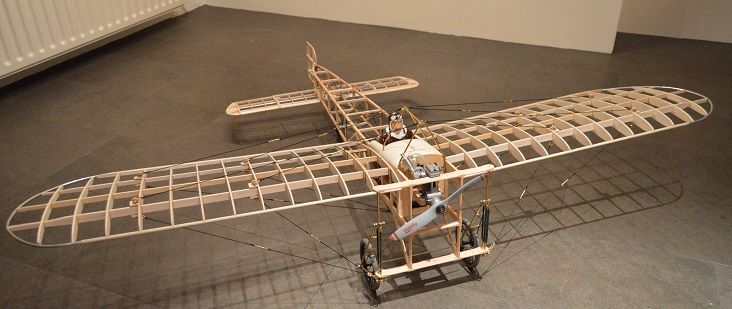

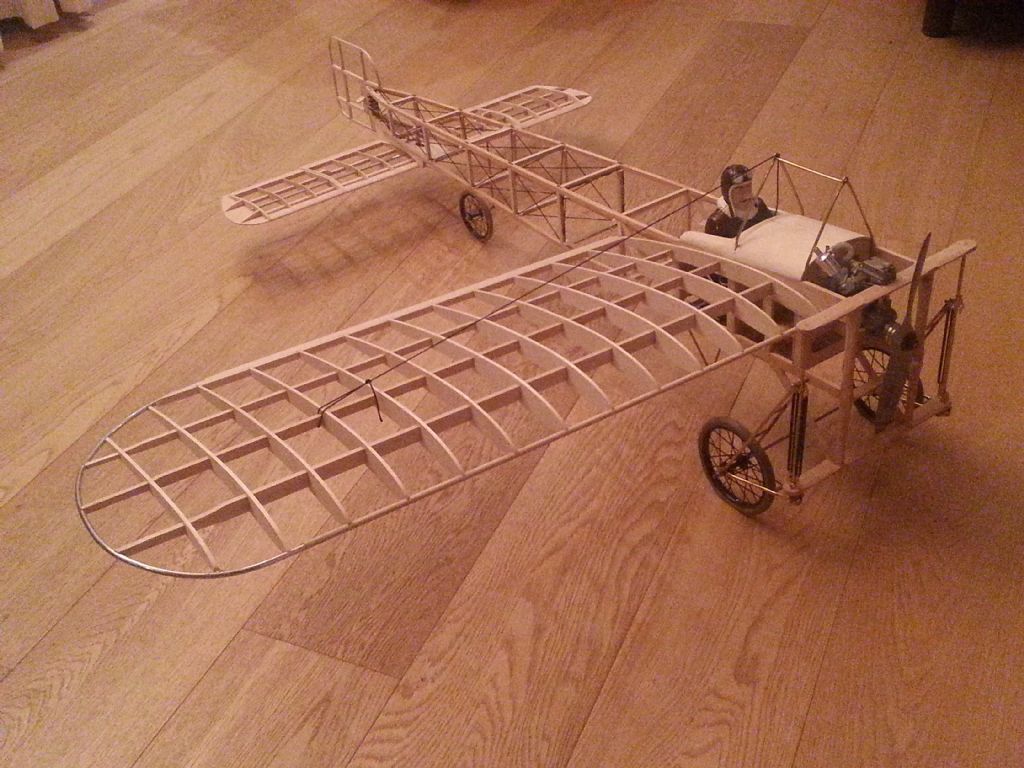

I‘ve been building a Bleriot XI for the last few months. I’m using a plan by David Boddington of a 60” Bleriot. (**LINK**)

I’ve done some modifications to get closer to the plane Luis Bleriot flew over the Channel in 1909. For example split stabilizer and roof-like strut. Now, when the building is well on way, I’m having some doubts.

Firstly, I decided to use the SC30FS engine. The plan recommended a PAW 29 which is a diesel engine. The SC30FS is probably not a very powerful for a 60” model, but the original ANZANI was probably not that powerful either.

Secondly, it looks like I will have to put quite a lot of lead in the front, to get the CoG right. According to the plan CoG is about 10 cm from the LE of the wing which is 34 cm from LE to TE.

I would welcome any thoughts, ideas or suggestions that could help me along solving these problems.

Here is a video of the landing gear that I think is working quite well

More pictures can be found at my web: http://flugmodel.weebly.com

Regards,

BirgirEdited By Birgir on 11/10/2015 20:53:02

-

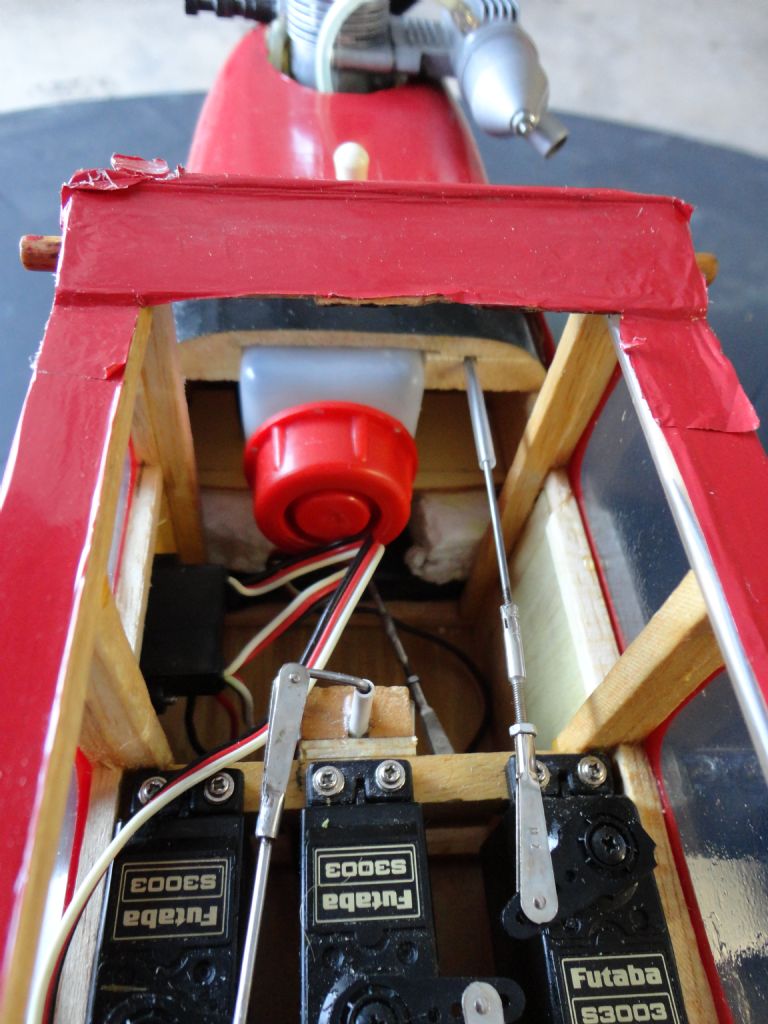

Before and after the rebuild. I also found a new location for the switch so it does not weaken the fuselages side. (Not that it would have changed anything in the last crash J )

During the crash investigation it was discovered that two of the nylon geared servos were stripped. One aileron and the elevator. Of course it could have happened in the crash but it is better for my self-esteem to believe that one of it stripped just before the crash. I have now replaced all my nylon geared servos with metal geared one.

B.

-

-

-

Problem solved!

I decided to do a "keyhole surgery" and replace the clunk tube. When I got the clunk tube out for inspection there was nothing wrong with it BUT in the clunk itself there was a wire filter the was partially clogged. I replaced the clunk and the tube.

After the operation, I tested the engine and now everything seem to be alright.

So after all, it was Kenking that was right – at least partially – the problem was due to disturbed fuel flow thru the clunk tube.Thanks for everyone’s help, it’s been a pleasure working on this problem.

B.

-

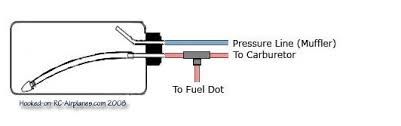

Yes, the red thing is a cap.

The setup is similar to this picture but the fuel pipes go through the bottom of the tank/flask instead of through the cap and there is also a fill pipe. The fuel pipe is a bit above the center.

This picture was taken during the last rebuild.

So now I must make a tool I can use to change clunk hose through the opening.

B.

Edited By Birgir on 27/02/2015 15:16:38

-

Hi and thanks to everyone for sharing their thoughts.

I finally made the Baker-test this morning and 12 points goes to Bert Baker

The clunk-pipe nipple is at the top of the tank so with a half tank of fuel I ran the motor full speed to be certain that the problem was still there. Then I turned the model upside down so the clunk-pipe was fully submerged in fuel and Vola! No problem. I did this several times to be absolutely sure.Of course there is a small chance that there is something wrong with something else that disappears when the model is turned over, but I think that the clunk pipe is a reasonable suspect.

So now I only have to figure out a way to change clunk-pipe through the tank cap. Doctors do heart surgery thru smaller holes so it must be possible.

Until then my Bleriot is coming along nicely.

Thanks,

B.

Edited By Birgir on 27/02/2015 12:12:22

-

Thanks kenking

I like your theory. If we take this line of thought a bit further it could also explain the forming of bubbles in the fuel line from tank to carb. As you probably know, when the pressure drops in a fluid, a vapour bubbles can form, just like boiling.

The boiling point of fuel must be rather low so this is probably not as far-fetched as it sounds. The boiling point of methanol is around 65 deg. so the fuel could have even lower boiling point than that. (I’m not going to test it.)

I wonder if it is possible to test this theory by putting an adjustable clamp on the fuel line from tank to carb. If that part is made a little narrower a cyclical phenomenon in the clunk hose should stop even though the engine might not reach top rev.

B.

-

Well, we actually do have Iceland in Iceland too – you know – so I got the pun, but thanks for the concern.

Maybe I will send some burgers over when I've done the test

B.

Edited By Birgir on 22/02/2015 19:01:41

-

Hi Ken

In Iceland

B.

-

Hi

I‘m still waiting for an opportunity to perform the Baker-test, i.e. checking if the problem still exist if the clunk pipe is fully submerged in fuel. Because the test needs to be performed outside I must wait for suitable weather, and it can be a long wait around here.

While waiting I’m forced to spend time on my next building project.

B.

-

35 miles each way, but I buy most of my stuff online from Pegasus Models. Their online service is also very good and personal.

-

“Our youth now love luxury. They have bad manners, contempt for authority; they show disrespect for their elders and love chatter in place of exercise; they no longer rise when elders enter the room; they contradict their parents, chatter before company; gobble up their food and tyrannize their teachers.”

Socrates, 469–399 B.C.E

B.

-

I do

My Keil Kraft Mini Super, build in 1973 is still going strong

This video is from last Saturday, 24th of January

Pictures of the last rebuild can be seen at **LINK**B.

-

Yes, Peter, I've met Murphy once or twice

Winter Flying

in All Things Model Flying

Posted

Thanks Mowerman for remembering us that live closer to the Arctic Circle.

We do fly, and we just dress up for the occasion.