-

Posts

353 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Steve Dunne

-

-

Well - we now have a baffled engine - better than a baffled pilot, eh??

The starboard inlet has a baffle to direct air to the top (cold) side of the engine.

There is a baffle (2) to tunnel the air past the cold side. The air must then pass down through the cylinders to the exhaust side.

Then a baffle (3) is there to redirect air that has come down through the cylinders to the outside.

The exit hole in the cowl is baffled over the cold side of the cylinders to force the air down through the cylinders.

All comments (even rude ones) very much appreciated, this is new territory for me...

Steve.

-

1

1

-

-

Jon - an excellent, informative video - thank you very much!

I now know what I must do, and more importantly, why!!

Steve.

-

Thanks for the good advice, Jon.

I'll block off the port side of the cowl completely, so the only airflow is into the orifice at the starboard front of the cowl, down under the front cylinder, then up around the rear cylinder past the exhaust side. I'll shroud around the needles, above the carbs, to try to keep the airflow more to the hot/exhaust side of the cylinders.

I'll also put baffles to keep the airflow nearer to the lower (hot) cylinder side (currently rather open!).

There is no exit for airflow either at the base of the cowl or at the rear of the port cheek, the air can only exit via the side around the cylinder heads - see picture..

The exit hole is about 2½ times the inlet hole area - I don't want to close it up too much more...?

Also - I have a Spektrum telemetry receiver (AR6600T), which I haven't used for temperature sensing before.

Questions for Jon (or others more knowlegeable than I):

Where is the best place to mount the sensor (bead thermister) to read the cylinder temperature?

What is the best method for mounting the sensor?

At what temperature should I start to panic? ?

Thanks for all the help, and sorry for all the ignorance...

Steve.

-

Thanks, Jon.

Your suggestions are different to what I had planned...

I was going to block off the entry point at the front of the port side of the cowl, and the port exit. That restricts the airflow to the starboard side of the cowl.

Second - baffle the whole port side of the cowl, so that no air gets below the mounting lugs.

Third, deflectors to guide the incoming air around underneath the front cylinder, then up around the rear cylinder to exit past the top of the cylinders.

I was trying to cool the top part of the cylinders? There is currently no exit for air at the bottom of the cowl - all airflow exits past the cylinder heads etc.

I'm not sure how I can apply your illustration to my installation, but I will study it for a while.

See "final fitting" photo above.

Your comments would be greatly appreciated...

Many thanks,

Steve.

-

Three more good flights today!

Jon - you are correct, there is a cooling problem. I am running richer than I should, getting only 7800 on a Menz 18x8. On two of the flights, after about 5 minutes, when performing a tall stall turn, the engine cut on the down line. It landed ok both times, but the engine was very hot. I think some much better baffling is in order before the next outing...

And sorry, no-one to take video yet.

Graham - this is the first engine for the AWXL - I didn't have anything suitable in the hangar!

E.D. - I too had the anodise problem, in the glowplug screw hole. Held the engine upside down, carefully ran a plug tap held in my figers a few times up and down, and everything worked ok. Please don't tell Jon...?

Steve.

PS Thanks to Nigel Castle for all the flying photos!

-

1

1

-

-

-

Very pleasant day's flying - with several maidens flights for models built during lockdown.

These are nine versions of Terry Anderson's new design "Hanky Planky" - a great deal of fun at high speed.

No, we haven't had a mass launch...

(Yet!)

Also flew the Acrowot XL with Laser 200 Inline Twin...

A very good day.

Steve.

-

5

5

-

1

1

-

-

I bought 4 a couple of years ago. The first three did not last long, and did not seem to help on starting.

I disposed of the fourth and returned ot OS-F plugs, which work very well for me in Lasers, OS 4strokes and Saito 4strokes.

Steve.

-

Keen to join in as a "Laser engined" meet - it is a special engine worthy of its own festival!

Would like to see peoples intentions as to what model they might fly at the meet, a little time before the event, so that we can bring complementary models.

-

Well, I went the route of colour mixing and got a reasonable match.

Now I need to repair some of the orange film covering. The model shops are closed to visitors so I can't go and look for a match. Does anyone know which film is a good match for tha Acrowot XL orange? Please?

Thanks, Steve.

-

Sounds great - I'm in!

Spitfire 180

Hurricane 180

Stampe 180

Mustang 155

Jungmeister 155

FW190 200VTwin

Wot4XL 200ILTwin (under construction)

Choice, choices!

May decide what to take depending on what else will be there - dogfights, formations etc?

Steve.

-

Hello all you Acrowot XL pilots - can anyone advise on the best paint to use to colour match the orange on the cowl?

Preferably fuel proof, but if necessary I can add fuel proofer over a good colour paint.

All this to save me the bother of longwinded colour mixing of fairly noxious paints!

Many thanks,

Steve.

-

Martin,

Inverted flight is no problem, unless you are doing it for minutes at a time!!

The 4oz tank acts just like a normal tank setup - the carb draws fuel as long as there is fuel to draw.

The hopper fill line allows air to get to the top tank, breaking any vacuum, but that just lets more fuel descend once the aircraft is right way up again.I don't do extended inverted flight with the Spit so cannot prove it, but long slow rolls are a regular and problem-free maneouvre.

Having said all that I can't argue with Jon's comments - you have to get it right, and to understand what you are doing with the fuel feed. Like anything else, really!?Steve.

-

Hi Bruce, Who was the careful owner? did you get it directly from him...?

.

.Some interesting suggestions - thanks to all.

Steve.

-

Thanks Philip - I should have been able to find that myself!

Thanks Philip - I should have been able to find that myself!

Steve

-

Has anyone got a Maxi-Lift? If so, would you please measure the length of the engine cowl, or the distance from the firewall to the spinner backplate?

I am looking to see what engine options I might have...

Many thanks,

Steve. -

Hi Martian - don't worry, there is absolutely no hurry for this!

Yes, it is a slide fit on a stub set into the wing. Unfortunately it slid off!!!

Had three flights on the Spitfire today, but without guns I was limited to reconnaissance flights...

.

. -

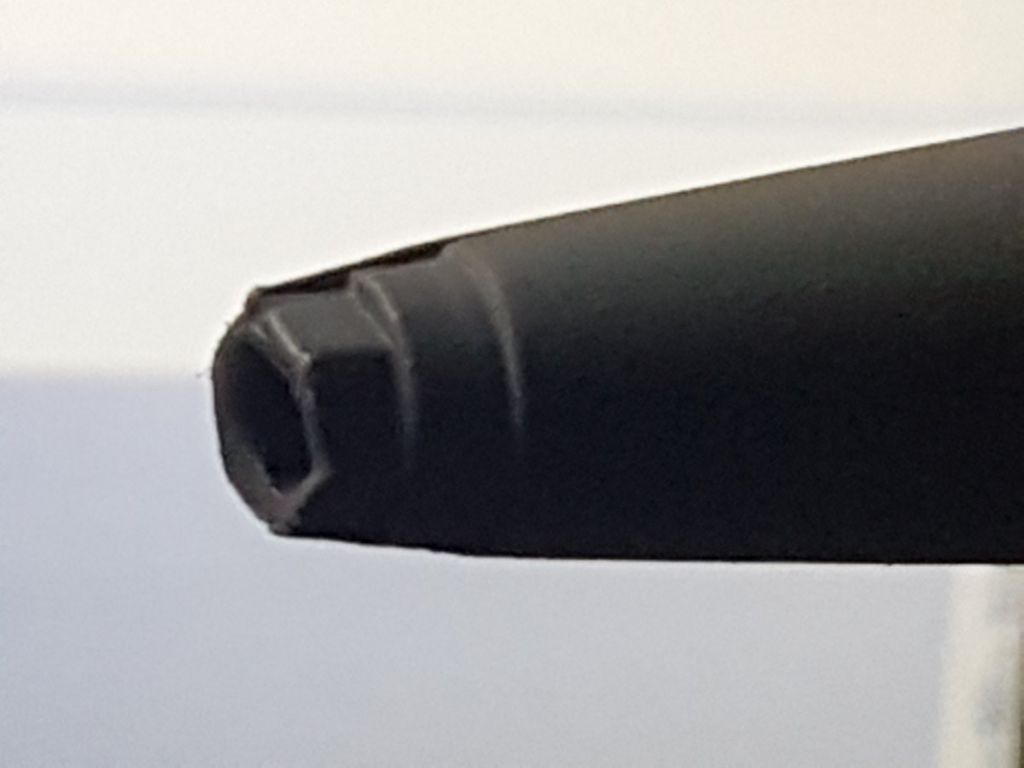

Just to note, the barrel is parallel at 20.5mm for about 60mm from the mount end, then curves in to the snout.

See pic 1.Steve.

Edited By Steve Dunne on 27/07/2020 14:50:36

-

Hi Martian,

I hope that the dimensions on these photographs are enough for you, I'm afraid I have no experience with 3D printing so may not be complete. If there are other dimensions that would be useful please let me know. I will happily reimburse you for the time and effort!

If it is not too much trouble, a pair would be desirable so that they match... .

.Thank you again for the kind offer,

Steve

The barrels are ~1mm wall, hollow all the way through.

Ignore the flashing at the end, where two halves were bonded together. It should have been cut off before I fitted them!Edited By Steve Dunne on 27/07/2020 10:39:07

-

I do - I will measure and get back to you.

Thanks!

-

I have the lovely Hangar-9 81" Spitfire - it has been flying well for the last couple of years. Unfortunately, when it noses over (not every landing - honest!) the cannons dig into the deck and sometimes cause damage to the wing leading edge.

I resolved this by making the barrels a slip fit over the cannon stubs, so that they will just pull off without causing further damage. This was great for a few flights.

There is always an "unfortunately...".

Unfortunately last flight on Friday, I noticed in mid-flight that one cannon was no longer attached to the wing. It could be anywhere in scores of acres of moorland grass...

If anyone has any H9 Spitfire cannon barrels that are no longer required, or can point me tro a source of same, I would be very pleased!

Many thanks,

Steve.Edited By Steve Dunne on 26/07/2020 17:44:31

-

Nicely done, Martin!

Great to see another Aeromaster in the sky.

They live a long time, too!Steve.

-

Hi Adrian,

I retained the castering tailwheel on both of my Stampes, and have very few issues in ground handling (no problems at all in the air...

).

).

The only time that the rudder is not enough is when trying to turn back out of wind at the end of the landing roll out, but then I find the same problem with my 1/4 Jungmeister and 1/4 Christen eagle both of which have steerable tailwheels.They can all manage it if I retain enough draught over the fin&rudder, but sometimes ground conditions make that difficult...

Go with it!

Steve.

-

Martin, The Svenson Stampe (foreground) is 1/5 scale, not 1/4. It flies on an OS91fs, with a 15x6 prop.

It was built over 30 years ago, so getting a little stiff and creaky (like me!).

The two Stampes are remarkably similar to fly, and caused no little confusion yesterday when I flew both

(not at the same time, we have to observe social distancing...).The old Svenson 1/5 scale weighs 9lb 2oz, the SLEC 1/4 scale weighs 18lb 2oz.

I haven't yet decided which I prefer to fly, but the 1/5 Svenson is far easier to get up to and down from my loft workshop, up the ladder and through the small loft trapdoor... .

.Steve.

-2.thumb.jpg.bb101ffa622e9a64a250523371013754.jpg)

-7.thumb.jpg.60db71f4b84e47ca8c6ed488b9a28cb1.jpg)

-7.thumb.jpg.443f9c81e709d8df604b21817fa61428.jpg)

-9.thumb.jpg.93793d1f6c71f82dacc1c6214248bce5.jpg)

Laser 200 in line twin - retro fit

in IC Engines

Posted

Ron, for interest, I had air feed problems at first, the rear carb going very rich, dragging the revs down, then rising back again, cycling over a 1½ - 2 second cycle.

This was apparently due to turbulence around the rear carb, very close to the firewall.

I gouged out a 5mm deep, 20mm wide depression in the firewall directly behind the rear cowl, and used silicon caulk to sculpt a bit of shape around the area.

The problem did not recur.

Steve.