David Oatham

-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by David Oatham

-

-

Thanks for your reply Big T.

Yes I am aware of the hang angle as I have built an Atom in the past.

The other factor that I'm unsure of is how much motor downthrust is required?

I assume the right motor thrust is looking from behind, and as a 'dyed in the wool' fixed wing guy this always seems odd as fixed wing motors tend to have a few degrees of left thrust. Is the whippet plan available anywhere do you know?

Dave

-

I have recently completed my 'Revolver' autogyro, and the instructions were quite clear on how to locate the CofG. This seemed reasonably straight forward by hanging the model from the rotor spindle and then by the noseleg. I understand that the motor thrustline must not be below the position of this, and in fact all seems OK.

My question is regarding how to find the CogG position on a tractor type autogyro rather than a pusher type.

I am in the process designing something along the lines of the 'Atom' but slightly larger. Also is there a rule regarding the height of the mast in relation to the fuselage / stabiliser? Any advice would be greatly appreciated.

All the best, Dave

-

On 29/01/2021 at 18:37, Richard Harris said:

Joakim,

As Tim suggests the wooden blades are straight forward to construct though the 3D printed versions seem to fly just as well.

Here is a video taken at our one and only get together last year, there is a Panther taking off at around 2.43 which has printed blades designed by Ian Smith. These are made in segments attached onto a carbon spar, the MK1 versions taped together but I believe the latest interlock together. If a blade gets damaged the segments can be replaced quickly and easily, its all very clever.

The tri plate is easy enough to make yourself, I print out the triangle onto paper and spray glue it onto the GF sheet, then cut out using tin snips before filing and sanding to shape.Aluminium for the UC can be bought from DB Sport and scale.RichHi Rich, I've just got my shiny new 3D printer (Artillery X1) and fancy having a go at printing some blades for my Atom and Panther models.

Where can I locate the STL files suitable for these models? I've looked at the 'Files' section for the group but don't see them there.

The ones that you say interlock sound interesting. Any advice on the printing side would be appreciated, for example which type of material etc.

Many thanks

Dave

-

Please include me in the draw too .... Happy Christmas everyone

-

Hi Andy, the only place I found for the dual u/c when I got to your stage of the Panther build was DB SPORT AND SCALE.

They were very helpful. Best of luck with your Panther, one day I'll get around to flying mine, but it always seems too windy lol.

Dave

-

-

Hi all, has anyone built the 'Roto- Duo' autogyro that was a free plan in RCME June 2019 edition? If so it would be interesting to know how well it performed.

As there was nothing currently on the building board, I thought I'd bash some balsa

. It's got 2 rotors that spin in opposite directions, but the only steering control is provided by the rudder, which to be honest looks rather small !!

. It's got 2 rotors that spin in opposite directions, but the only steering control is provided by the rudder, which to be honest looks rather small !!

One more thing, does anyone know how I can remove the windings of a couple of old brushless motors. These will be the bearings of the two rotors. I have successfully removed all of the magnets using a hot air gun but i'm struggling with the windings.

Cheers for now, Dave

-

Hi Stephen, I like your idea. How have you used a drawer runner in your shaper, and how do you ensure that the prepared blank blade remains in the correct position during the sanding process?

Cheers, Dave

-

-

Hi Andy, you will enjoy building your Panther I'm sure. This thread is VERY long as you will have discovered, but from my experience it's worthwhile wading through it. There are (or at least were) a few minor errors on the plan, but that is no criticism of Richards design. Regarding the top spindle, I did as was suggested and placed a 'Wanted' ad on the BMFA Classifieds and picked up one for £10.

My Panther is still awaiting its' maiden flight which may take place this Sunday, weather permitting

Enjoy the build !!

-

-

Thanks Steve / Rich,

Well it wasn't quite as straight forward as I thought replacing my OS40 FS with the 52, it almost fitted!! Some mods to the cowl were required but all good now. I'm almost t of excuses for flying my Panther, but I'm soooo glad I re-read parts of the forum regarding balancing. I had made the classic mistake of carefully balancing the model without the rotor blades fitted. Having re-checked the CG with the rotor fitted, she now is a bit tail heavy, which is annoying as I had to add some lead under the covering below the tail to balance her previously

Oh well, out with the scalpel later to remove the deadweight.

I've also decided that maybe I need to make more dust to produce a canopy .... Phew, 2 more reasons to delay 'Lift-off'

-

Thanks guys, that's my mind made up on that score

-

Thanks Rich, that is really encouraging

I have applied the covering exactly as you suggested.

I now have to decide whether to fit the OS 40FS that I have sitting ready, or whether to raid another model of mine containing an OS 52FS. In your experience, do you think the OS 40FS would be powerful enough?

The estimated all-up weight seems to be about 4.5lb without fuel.

Dave

-

Hi Richard, covering almost complete now and loosely based on Ian's and Trevor's schemes. It has gone very well and is looking the cats whiskers

, however I'm a bit concerned about the weight-gain of the blades once covered. I decided to use the sticky-backed plastic method mentioned somewhere in a forum by yourself. The blades weighed 51 gm each prior to covering. I've only covered one at present, and it now weighs 64 gm

, however I'm a bit concerned about the weight-gain of the blades once covered. I decided to use the sticky-backed plastic method mentioned somewhere in a forum by yourself. The blades weighed 51 gm each prior to covering. I've only covered one at present, and it now weighs 64 gm  . Does that seem too heavy? If so, what would be an average ideal weight of a blade 55 x 7 cm?

. Does that seem too heavy? If so, what would be an average ideal weight of a blade 55 x 7 cm?I'll post some photos when it's finally assembled

Dave

-

Hi Trevor' I'm not sure what an MEC gearbox is, I bought it from a guy via the BMFA classified ads

I just love the colour scheme of your Panther, would you object to me doing something very similar?

Dave

-

Hi Richard,

Thanks for your reply and advice. As suggested I removed the second layer of the rotor plate on my 'Atom' and ventured back to the field on Thursday. Once the nasty weather conditions (strong wind and rain

) had subsided, I summoned up the courage to have another attempt an not going home with a model to repair. As suggested I allowed the rotor to spin up to a nice speed and gently gained forward motion at walking pace. At this point it was soooo tempting to pull back on the stick, but forced myself not to as per your advice. Then .......success! Lift off

) had subsided, I summoned up the courage to have another attempt an not going home with a model to repair. As suggested I allowed the rotor to spin up to a nice speed and gently gained forward motion at walking pace. At this point it was soooo tempting to pull back on the stick, but forced myself not to as per your advice. Then .......success! Lift off

The model was a bit lively and it wasn't a pretty sight, initially frantically fighting the blustery wind, but never-the-less successful .... Phew

. Once the nerves had settled, 2 more successful flights were made, so at that point I went home well pleased, and more importantly with an intact model.

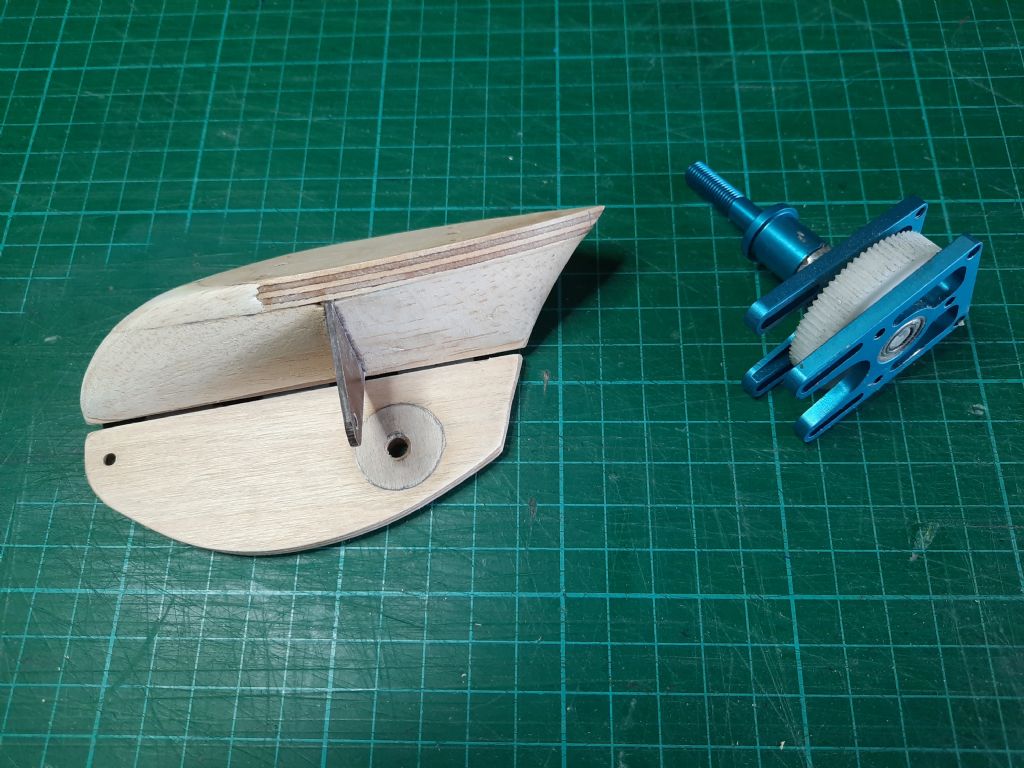

. Once the nerves had settled, 2 more successful flights were made, so at that point I went home well pleased, and more importantly with an intact model. Regarding the 'Panther', most of the build is now complete and I'm currently working on the rotor blades. I've attached a couple of photos of the 'unclad' model.

Dave

-

Hello Richard and all reading this forum.

Being a fixed wing pilot of more years than I care to remember, I am quite new to the world of model autogyros. I'm currently gradually getting the hang (excuse the pun!) of flying my first model, the Atom. I was interested in your reply to Richard Franks' problem where you mention that his head plate may be too stiff. Because I've now broken several head plates on my Atom due to take-off 'incidents' (model always rolling left on lift-off), I've now doubled-up to have 2 layers of gf plate (2 x 0.8mm) on the head plate. presumably this is a bad idea?

Following on, I'm currently building a Panther which is coming on very well, and I am going to power it with an OS 40FS. I was planning to use some paxolin sheet for it's head plate which I think I've seen mention of in this forum. I am now a bit concerned as paxolin doesn't flex very much

I would be grateful of any advice / comments.

Dave

Autogyro CofG locating?

in Autogyros

Posted

Thanks Richard, that's all very helpful. I'm glad you mentioned the vertical CG as that was my initial query. How can you locate / estimate the vertical CG on a tractor model?