Wasaforumite

-

Posts

165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Wasaforumite

-

-

John, Thanks for the suggestion. Anything with fibres impregnated won't cut using a hot wire cutter. The foil surfaced boards aren't really suitable. A lot of these companies have minimum orders.

Foam wings used to be popular. I wonder if people still do them and what do they use?

Trouble is at the moment I can't go nosing around Builders Merchants.

-

I started a thread on this plan recently but it got lost in the changeover (and messages I received about it).

Initially I was looking for solutions to building the retractable undercarriage that is briefly mentioned in the article but not shown on the plan. It seems nobody has tried to build this little plane , which is a shame. I'll have to muddle through.

The plan is all foam construction using what was originally called 'blue foam'. I am trying to source a modern equivalent but from what I can see it is very pricy stuff and it would be cheaper to use balsa. Also the problem with foam is the high cost of postage which sort of doubles the outlay.

It could be that builders merchants sell something equivalent - the question is what? Suggestions please?

-

Perhaps a little more down thrust on the Arising Star would help here?

-

I've not been able to read all 18 odd pages of this thread so I might Have missed earlier comments about under 18's not being able to register. How is that going to work?

-

Nik

Many thanks for your comments. I've now updated the software as you suggested and will have another session experimenting.

I'll report later. Ian

-

I got one of these combos from Airtek last year and have only just got round to installing the receiver in a plane (a HK Tundra).

I've fathomed out most of the features but I'm struggling with two issues:

1. It doesn't seem possible to mix down elevator with 45 deg flaps - it only mixes on full flaps. (using 3 position switch).

2. I just can't fathom how to get into the stabilisation menu to set up the Falcon 12 in this mode.

I can't really recommend this combo. There is no servo slow and there are only the two sticks plus one rotary control. All the rest of the channels have to be controlled by switches or mixes. The instructions (pdf download) are not well translated and seem to miss out stages. There doesn't seem to be much UK support either. I confess to being easily confused by the two level programming - some processes can be programmed in the tx and others in the rx using the tx.

On the plus side the transmitter appears to be well made, is quite light to carry around and has a good range. These plus points mean that I will probably just use it as an expensive 2 channel job for RC IOM yacht racing, where I've lost signal using a Spectrum DX8 and carrying a TX round ones neck for 3 hours certainly makes the weight an important factor.

I would certainly appreciate comments and tips from other users.

-

Jamie

I see no one has helped here.

I changed to an iMac a month or so ago having had windows Pc's more or less since their inception. I'm afraid I've regretted it.

I'm prepared to accept the learning curve involved but I don't find many performance advantages over my 5 year old pc (with ssd). Granted there's less cables and boxes and the display is good but the latest Dell all in ones come with good screens and are cheaper. The lack of a back button on the mouse when browsing is a real pain.

The disadvantage as you are finding out is that there is much less software available. There isn't as far as I have found any modern rc flight sim software. This also applies to quite a lot of other categories as well. For instance my solar panel inverter has a little piece of software for me to check its performance installed on my pc. Nothing available for the Mac. Similarly no Power Director video editing software etc...

With Android phones now rivalling the iPhone I really don't see the need to switch to the Mac and I wished I hadn't.

Hopefully, this will resurrect the thread and maybe someone will come up with a suggestion for software we've missed.

-

What I find interesting about this is that I believe that Vauxhall's current vans (built at Luton) are similar/same as Renaults but their new van will have to be a Peugeot Citroen. Bit like Italy changing sides in WW2!

I had a Peugeot 406 Estate in 2003 and it was a brilliant car let down by dodgy electrics. My current 2016 Mondeo Diesel Estate is also brilliant and so far reliable - much better in fact than the 2015 Mercedes C250 Estate I had before it that I had to get rid off before the Warranty ran out because it had so many problems.

-

Had a chance to test one of the motors today. On a rather tired 3s lipo that I had hanging around, the motor used 155 watts. This is about 15 amps. The propellor used was a 9x6 APC E series. From postings on a US forum this should be enough to give a lively performance with a short take off run. Flight times should be around 15 to 20 minutes. This assumes the total weight of the plane is around 4 to 4.25lbs. Fingers crossed!

I've sorted out the wing servos. Next jobs are the rudder and aileron servos. After that it's covering, a job I never look forward to.

-

I've heard some good reports about Hobbyking film. I may try it on my next build. For this one its going to be Solarfilm white and blue on the wings and Oracover white for the fuselage. I wanted some extra strength in the fuz. I wasn't aware that the HK stuff was as strong.

The ESM Ottter must be a rarity now. It looks a lovely kit and I have to say the fuselage particularly is a lot more realistic than this plan because the moulding allows for all the curved surfaces of the original. Hoperfully, the all balsa build has some virtues. It will probably turn out a bit lighter and at least I can build another one if the worst happens!

-

Would be nice. I'd need to source a couple of 1/12th scale head and shoulders pilots - any ideas?

Readers may have noticed that I changed my original plan of having one battery powering both motors. I realised I'd need some 4000 3s lipos and none of my other planes would use them. Two 2200 will give the same result for less outlay. Hopefully these common lipos will be reliable as they are so popular these days.

-

Building has been slow recently, held up by the holidays and the time consuming work of constructing the engine nacelles and ensuring that the ailerons matched the wings properly. I have now nearly finished the construction work and have made a start installing the motors and wiring.

The nacelles are built by planking over formers so with a top and bottom it is like building 4 little rowing boats!

The motors, are Emax GT2218/10 (about 1000 rpm/v) obtained from Totem Hobbies, Plymouth. I found it quite difficult to source motors of the right size. Most places only had 1 in stock!. Using 9 by 6 props they should draw about 15 amps each on 3 cells. If this isn't enough thrust I can go up to 10 by 5. Motor tests will take place when I can be bothered to go out in the horrible weather! I am using two 30 amp opto ESCs. Power for the Rx will come from a LiFe battery and voltage regulator.

Roughly balancing the model on my fingers, the c of g seems about right and the correct balance should be possible by moving the batteries around. I intend using 2 3 cell 2200s as these are a popular size. Each motor will have its own battery so I will get new batteries and keep them in pairs.

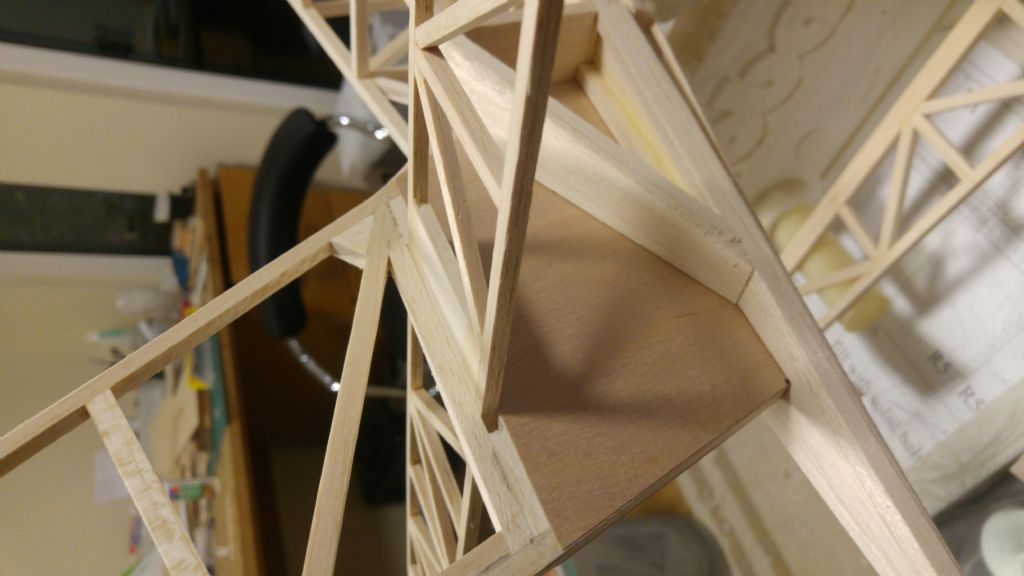

Here are a couple of pictures of the airframe so far. The control surfaces remain to be attached.

-

It would seem that Granville Brothers Aircraft Co. had a very high ratio of pilots kiled/injured compared to the total production of their planes. I counted at least 7 deaths and plus a number of injuries on the Wiki page.

-

When I cut out parts using a fret saw or scapel, I just photo copy (or printout if the plan is a pdf) the plan using an Epson Workforce scanner/printer. The copies are cut out with scissors leaving a margin of a couple of mm and then stuck to the wood using a Prit stick. After cutting out the paper is easily removed. I did buy some A4 labels to peel off and stick after copying or printing which might be even easier but I've never got round to trying it yet.

-

My final posting today just shows the splitting of the ailerons from one of the wings. This is not a job I have been looking forward to as it is difficult to measure where the cuts go. The new trailing edge can be see (oversized before planing and sanding).

I have had some graphics arrive from Callie in the USA. I will be dressing the plane as a WinAir Twin Otter, mostly white, with stripes, blue tail and wing centre panels and red rudder. I decided against the yellow Canadian military strip as it has been done before. Similarly, I avoided the US para team. The former was available as a VMAR ARTF, the latter a Hangar 9 ARTF. For those impatient to haqve a new Twin Otter, I saw on Ebay that a German ARTF manufacturer is doing a Swiss survey liveried version (very nice it is too). It's rather expensive and with the power trains it will cost about £400 to get into the air plus battery and radio. Mine will cost about half that even after buying Oracover.

-

This time there is a photo of the tail mocked up. Others who have made this plane have said that although the tail seems to work OK it is rather prone to damage when the plane is handled. The main problem is weakness of the fin. I have doubled up some of the frame and used 1/64 veneer each side of it under where the stabiliser or tailplane is fitted. It is much stronger as a result. I am going to use two Savox 225mgs to operate the rudder and elevator, deleting the two heavy standard servos in the middle of the plane under the trailing edge of the wing.

-

This is the stage where progress seems to slow. Work becomes more to do with details that creating structures.

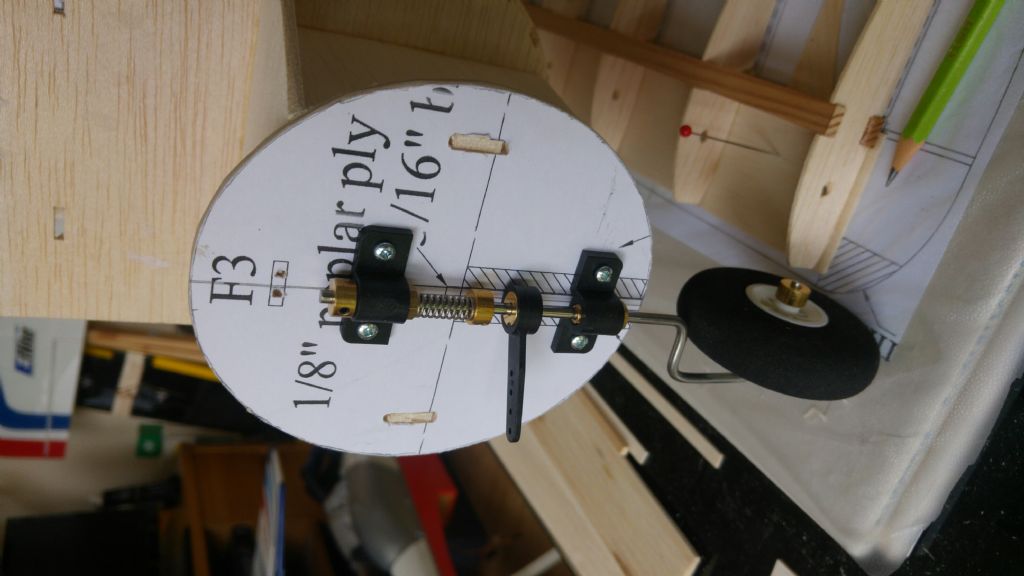

I am trying to keep to the original plan as far as possible because it was the basis for a commercial kit many years ago so it was basically well sorted and also modifications usually mean more weight. However the photo below shows a depature from the plan which had a standard servo in the middle of the plane operating the front wheel and the rudder via long control rods.

I have used a sprung noseleg, I believe it is a Dubro part but i've had it so long I could be wrong. Also a small metal geared servo is used for steering with control wire bent in a elongated 's' shape (not visible in pictures). This should have some shock absorbing properties as a result. The servo is just under the cockpit of the plane.

-

I am responsible for the membership in our Club as well. The new system of on line renewals is a huge improvement together with the facility for on line payments. There is one further improvement that could take us up a further level. It would be useful to be able to print off a list of members from the the website to be able to check our work without having to wait for the list that comes with the certificates.

I did email the BMFA about this but didn't get a reply. (which I am afraid is quite typical).

Dreaming on........Having electronic certificates for one's smart phone would take us into the 2010's and save alot of messing about as well as postage. Maybe by 2025?!

-

I was in Als this morning and all they had were G Force modules (can't think why I would want one of those?) nothing else. Good news that we can get Spektrum stuff serviced but will level of service match HH UK centre before it closed I wonder? The 50% increase in prices is still an issue. Yes I know the exchange rate has moved against sterling but the dollar prices in the States seem to indicate a little mickey taking.

-

One of the best features of the DX9 and other Spektrum transmitters is the 'talking' telemetry. After having a problem with Lemon telemetry, I thought I would use the original TM1000 module that came with my transmitter. I was interested in an altimeter. I find that when they were sold by a wide range of retailers they used to cost around £50. There are very few for sale now (Als Hobbies don't have any stock for instance) and even those retailers willing to sell them on the web want £76 for them, an increase of 50% (approximately in case BEB is watching!).

If I was willingly to run the gauntlet of buying on Ebay from a seller in the USA the price is $49 (about £35) plus postage, VAT, Royal Mail tax etc,

This price increase I believe is fairly typical of Spektrum products and with the closure of their UK service centre factored in it would seem they are sending a very clear message to UK Spektrum users. Sort of 'Goodbye!'

-

I have an AXI 2826/12 that has very noisy bearings and needs an overhaul. Apparently, there is a kit available from Electric Wingman. That's a good thing. The bad thing is that AXIs are reputed to be difficult to take to pieces.

Has anyone done this? How did you get on and what tools did you use?

Hopefully, someone can help, please?

It is surprising that there is very little on the web about this, there appears to be no UK repair centre and the AXI website makes no mention of service. One might think 'not good enough' considering the cost of the motors.

-

I've started on the wings now. I have decided to build the wings entirely as normal and then cut the ailerons out. Similarly the engine 'gap' will be cut out later. The ribs have holes in them for the wiring. I never seem to be able to make a good trailing edge by camfering the top sheet and sticking it down along the edge to the bottom sheet. Instead i have planed the edge of the wing and glued on a 3/16 by 3/16 strip. This is then planed and sanded to an edge about 3/32 thick.This is a similar idea to when trailing edges are put on foam cored wings.

There are two relatively inexpensive tools I use all the time. One is a plastic ruler with notches to gauge balsa sheet thicknesses. The second is a Great Planes sanding bar about 2ft long. Both seen in the picture below.

The fuselage has had some stringers added and part of the nose. So far it is entirely as per plan. I'm not quite happy with nose in the original design, it looks too 'beaky'. This is probably because the designer wanted to make construction simple avoiding compond curves. I'm not about to make it more complicated. I just think by shortening it a couple of cms it will look better even though it will be less to scale.

Edited By Wasaforumite on 20/10/2017 22:30:21

Edited By Wasaforumite on 20/10/2017 22:30:54

-

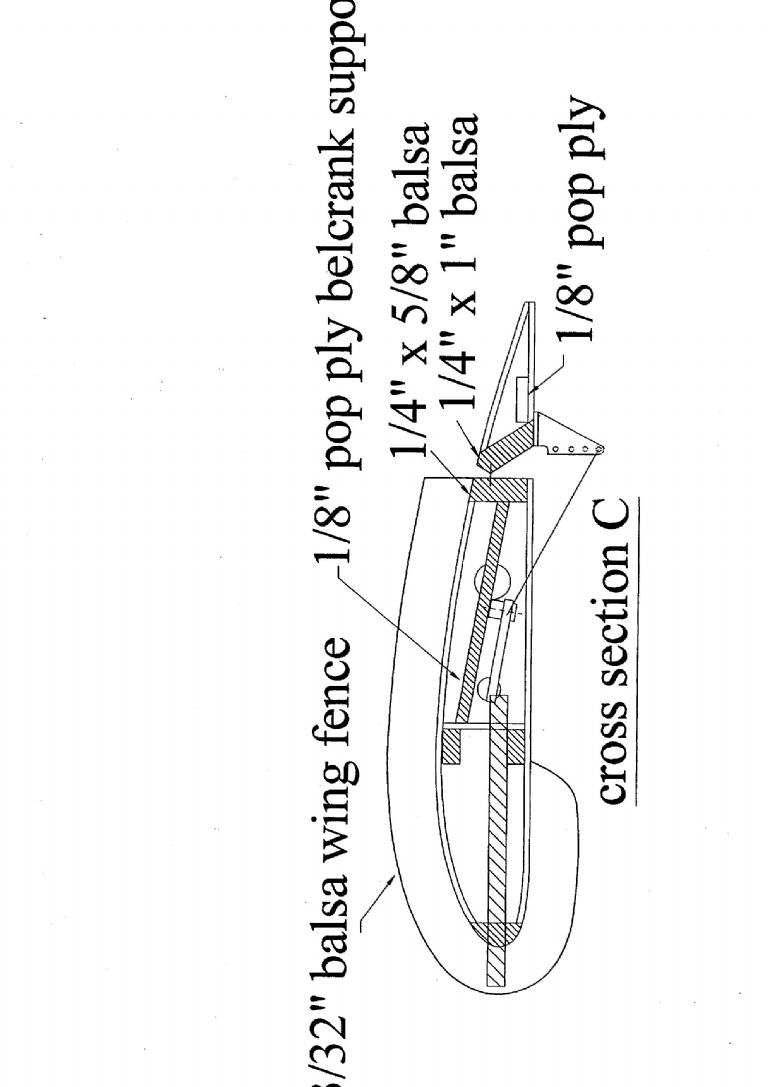

Sooner or later I am going to have start on the wings. There are in set ailerons and I am showing the catch-all cross section here. The wing is easy enough, looks like Clark Y but I have some fear about building the ailerons. I really prefer to build them as part of the wing and cut the out but it doesn't look like that is possible here. The idea of getting an accurate chamfer on the 1/4 sheet aileron leading edge of the aileron looks very challenging as well as building using fiddly little triangles. I going to have to think of a another way.

I will be using separate aileron servos and no bellcranks.Servos are one of the few things that are cheaper than in 2004!

-

Beech 18 by Cyril Carr (June 2012)

in RCM&E Plan Builders

Posted

I think I've the foam materials sorted for this now. Thanks for the suggestions.

I'm thinking of using the Elite 10-15 retracts. Every picture I've seen of these shows them folding sideways i.e like a Spitfire. Does anyone have experience of them when they are used with the main wheels folding back as in the Twin Beech? When used sideways the landing loads are taken by the mounts. When used fore and aft the loads are taken by the mechanism - is it up to the job? Perhaps I am mistaken how they work? Comments welcome, thanks.