-

Posts

124 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by EGB 953

-

-

13 hours ago, David Davis said:

This might be suitable for your engine. It's cheap enough but it could do with a clean. https://www.ebay.co.uk/itm/355534920581?itmmeta=01HTWSZWXSYGJ193VZ1JVBTGB2&hash=item52c7885b85:g:EDcAAOSwIvdl7xjg

Thanks, I measured the gap between the mounting holes and it is 37mm. As luck would have it I have found a silencer for an Irvine46 that fits nicely.

-

1

1

-

-

52 minutes ago, Engine Doctor said:

Hi EGB. The weston silencers or pipes are tuned for outright performance or throttle responce and are verh good . Your os silencer mising part is likely the same size as those fitted to many chinese clones like ASP, SC etc. There are loads about secondhand have alook on ebay and check mounting hole centers. Also measure the inside diameter of the exhaust you have and you may

a used end cone and through bolt on here .

Thanks! Will browse this afternoon! Good to know there’s a fair bit of standardisation.

-

32 minutes ago, David Davis 2 said:

Good Morning EGB!

Just Engines offer a range of silencers, either standard or "quiet," which will suit your engine. In order to be sure, just measure the distance between centres of the mounting holes, dimesion "c" on the drawing. They claim that their silencers with 35mm between the bolt holes will fit an OS engine which has 35.5 mm spacing. https://www.justengines.co.uk/product-category/exhaust-systems/two-stroke-exhausts/standard-mufflers/?v=11aedd0e4327

A range of special exhausts is available to order from Weston UK. I had one made for an SC 32 and it is very impressive though they are more expensive than a standard silencer. https://www.westonuk.co.uk/Genesis-Pipes/

Good morning!

thank you that is very helpful, I will measure up and get in touch with them. What are the advantages of the specialist ones? Better engine performance?

-

Just acquired a lovely first series Acro Wot from a gentleman who no longer flies.

All looks in decent nick, except for the silencer on the OS46SF engine, which is missing the rear casing - it apparently fell off in flight some years ago.

it doesn’t seem that easy to replace, in looking at the manual an OS873 silencer is specified but I don’t seem to see many of those available.

are there other options? Are silencers fairly standard or do you have to go with one specified? Do all engine types have different sizes or would the silencer for a more recent OS 46 fit?

-

Ah brilliant, thank you!

-

Later today I will start covering the wing on my build, using Oracover. I plan a two tone scheme with the base being creamy white and the wing tips and LE in sky blue. Having not done very much wing covering in years, any top tips on critical do’s and don’ts? My thinking is do the bottom side first but don’t shrink till the top side is covered. Any other advice?

-

Thanks very much that’s very helpful.

-

1

1

-

-

Finishing a Ben buckle style 25-30 size plane with a wooden engine mount. Unsure on two things:

1. Should I use wood screws and attach directly to the mount or bolts?

2. Should I use those brackets/plates (not sure what they are called) as opposed to attaching engine directly to the wood? I like the idea of the brackets as you gun make small adjustments to engine alignment.

Any advice much appreciated, I haven’t used a wooden mount before.

-

can i confirm the deadline for responding? Is it 10 January? I will update my clubmates.

-

Sorry, this may have been covered and it is a looong thread. has the BMFA taken legal advice, if so, from whom and have they considered some of the EU human rights legislation related to privacy and proportionality? Just asking.

-

3

3

-

-

This is a fantastic forum - to have access to the collective wisdom of you all - it is greatly appreciated.

-

2 hours ago, Nigel R said:

I'd probably bend the ends of that wire over at 90 deg, glue / bind them to a hard balsa block or short length of hardwood dowell, then bind a third short length to go to the servo. Nylon thread, epoxy, some scrap wood, would take only a few minutes to do.

Certainly permanent enough for a 25 size airframe.

Effectively, a (very very short) dual pushrod - which were common (as kc noted) on old 60 size aerobatic airframes in 70s/80s/90s.

Two micro servos also works fine, but the single standard servo install is already there.

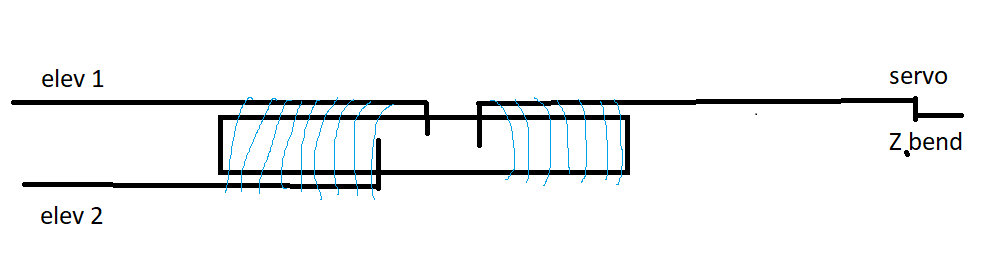

This looks a pretty practical option and your explanation is much appreciated. getting two elevators to be perfectly aligned might be very difficult though, any suggestions on how i might go about it?

-

3 hours ago, kc said:

Aerobatic models often use a ' forked pushrod ' made by bending both wires in to meet the central pushrod then binding and soldering. Less chance of an elevator failure due to a loose screw?

That makes sense or the suggestion of separate servos, this is for a small plane (25) so not expecting too much stress. My soldering is pretty bad so the risk may be worse that way.

-

-

Make it even harder to fly in a local park or field is just going to make it less likely a young kid, given a model for a birthday or Xmas gift is ever going to start in the hobby. This regulates us into decline.

is there a legal challenge around proportionality of the regulations?

-

2

2

-

1

1

-

1

1

-

-

Perfect. Fingers crossed it looks good!

sent a message to your inbox.

-

Good idea! will have to be later friday afternoon.

-

Indeed Jon 🙂

Laser 5 (normal oil one not the low oil variant), previous owner only uses laser 5 as well, zero sign of castor anywhere i can see.

13 X6 prop.

what's best, post to you recorded mail?

-

So,

I bought a Laser 70 in an Acrowot from another flyer at our club - he is a good modeller and pretty meticulous. Anyway having left it a bit for various reasons, got it out and flying around a month ago, with this chap's guidance and help. he helped me tune it and it has been running like a dream. Up to yesterday has around 10 flights of around 5 minutes each with it.

Yesterday started up first time, ran her up to full power for a few seconds then throttled back and checked transition - all good. Took off (full power) then throttled back to around 50-60% and flying around just some wide circuits nothing odd. all of a sudden a mild "pop" sound and engine is dead, dead stick back to runway - luckily no damage.

Now the first odd thing is the prop was lose with nut and washer rattling in the spinner.

Took the cowling off and engine out. Front off showed the con-rod has snapped right at the bottom where it connect to drive shaft (is that the right term). As far as I recall from my poor knowledge. of engines, con-rods only snap due to over revs or heating (too lean). M y suspicion is likeliest cause is prop not not tight enough, come loose and engine then over revs, but not completely sure. Hard to believe over heating as at medium revs and well tuned.

Anyway I attach an image.

So my questions:

How do I get a new con-rod (Laser site is offline and I dont have number)

it looks easy to replace but are there any key steps top include/avoid

Do I need any special tools (I dont think so - the design of the engine looks very clear)

How do i avoid in future?

Your collective expert thoughts very welcome.

Many thanks in advance.

-

Thanks All, very helpful!

-

1 hour ago, Jon - Laser Engines said:

yes i am back at the coal face now.

The other guys have it covered, 13x6 would be my recommendation. Just remember to lower the fuel tank to the fuselage floor.

Thanks! much appreciated. yes on Tank placement, I will need to do some minor surgery to sort that.

-

What’s the best prop size for a laser 70? Am planning to run it in the BH chipmunk.

-

50 minutes ago, Cuban8 said:

I see that the old 148/4001 series of Futaba basic servos aren't listed on the three large websites that I just glanced at - not even Servo Shop, unless I overlooked them - have they finished producing them all together?

Most affordable basic Futaba servo seems to be the 3010 priced at around £22 (out of stock though) - quite an increase on what a beginner would pay for a 4001 a while ago. Cheap fakes still on Ebay which is not helpful.

Hitec offers some reasonable servos so all isn't lost - I tend to use their well priced ballraced offerings in various sizes and powers now.

Thanks, I will get some decent replacements.

-

I recent bought a second hand air Frame with all the servos and engine. Having Done a full setup all the servos are ok except the rudder one which doesn’t return to exactly the same place when you pull full stick to the right versus the left. The servo is a 148 Futaba indirect drive. I have removed the servo and checked the cogs which are all clean and in good repair. There is no wobble in the linkage. Do I just consign the servo to the scrap heap? Not sure what else to do. Any suggestions or recommendations welcome.

.thumb.jpg.507e8e41f64a8a0ae8fbd699d456cbca.jpg)

OS silencers

in IC Engines

Posted

Thanks, I have sourced one already but that’s a great spot.