-

Posts

4,185 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Martian

-

-

-

Hi if any budding Tempest builders are interested on MORE4 episode two Warbird Workshops is about the rebuild of the UK,s only flying Hawker Tempest

-

1

1

-

-

A sad blow RIP Chris 😒

-

1

1

-

-

-

-

A bit long winded but should make you titterThe pastor asked if anyone in the congregation would like to express praise for an answered prayer. Suzie stood and walked to the podium.She said, "I have some praise. Two months ago, my husband, Frank, had a terriblebicycle accident and his scrotum was completely crushed. The pain was excruciating and the doctors didn't know if they could help him."You could hear a muffled gasp from the men in the congregation as they imagined the painthat poor Frank must have experienced."Frank was unable to hold me or the children," she went on, "and every move caused him terrible pain."We prayed as the doctors performed a delicate operation, and it turned out they wereable to piece together the crushed remnants of Frank's scrotum, and wrap wire around it to hold it in place with metal staples." Again, the men in the congregation cringed and squirmed uncomfortably as they imagined the horrible surgery performed onFrank."Now," she announced in a quivering voice, "Thank the Lord, Frank is out ofthe hospital and the doctors say that with time, his scrotum should recover completely."All the men sighed with unified relief. The pastor rose and tentatively asked if anyoneelse had something to say.A man stood up and walked slowly to the podium. He said, "I'm Frank." The entire congregation held its breath. "I just want to tell my wife that the word is sternum."

-

4

4

-

8

8

-

-

-

-

16 hours ago, PatMc said:

Thanks Ian, David & Martian for the info & good wishes.

Martian, the HoLEP op involves passing a telescope (Not James Webb proportions I hope !!) through the urethra & using laser fibre to do the "re-bore" then chop up & remove some more bits of the prostate. So it's front door entry not back door like your neighbour.

In the mean time I've received a 4 month action plan starting tomorrow with a review by telephone then some more tests etc finaly to be offered to be added to the waiting list for HoLEP. If the opportunity arises I'll ask to be put on the list before the 4 months is up.

Any further info will be gratefully received,

Pat.

good luck Pat hope it all goes well

-

1

1

-

-

On 30/10/2023 at 13:30, PatMc said:

Has anyone any experience of Holmium Laser Enucleation of the Prostate (HoLEP) ?

I am to be offered entry onto a waiting list for this procedure in the next month or so & would like to know as much about the pros & cons of the options available if I agree to go ahead with the operation.

Also would like to know how much long term real life benefit & detriment (if any) experienced after the procedure.

Thanks in advance for any info.

so in answer to your question take the opportunity with both hands you are fortunate to be offered the chance.

-

1

1

-

-

Here is another method done in 2022 link

-

I haven't had an opportunity to speak to my neighbour but I'm pretty sure he had a Holep procedure (his prostate was extremely large and causing quite a few problems) the procedure involved going in through the wall of the rectum into the prostate sac breaking all the prostate and flushing it to the bladder then after flushing the bladder his PSA reading were in the high twenties ,the sac is left intact .afterwards he had some discomfort which improve quickly within two months, during the recovery he had to wear pads. His whole life has changed from be afraid to go anywhere to hardly being at home to quote him it made a major change to his life, his PSA reading are less than 1 now. he had this done early this year the waiting list was horrendous so he opted to go private being in the enviable position to be able to afford the 8 grand it was that or a new kitchen. The rebore procedure that has been spoken about is called TURPS and as I understand is quite painful for sometime after not always completely successful and often patient is left with urine drip . It really is a localised lottery as to what is available on the NHS. Hope this helps

-

-

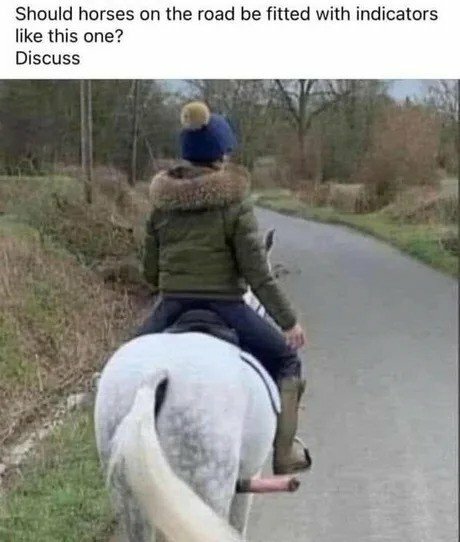

and they didn't have to worry about breaking the 20mph speed limit

-

1

1

-

-

hi Dave have sent you a message

-

-

I see Nick Owen is returning to his news desk although only 1 day a week he is extremely fortunate after extreme Chemo and surgery he appears to be recovering well. A for me my psa levels continue to rise but only very slowly but the difficulty in passing urine is getting very difficult I guess I should be having that conversation soon instead of putting it off . I hope all you other guys are coping well and keep spreading the words GET CHECKED !

-

12 hours ago, Peter Miller said:

Maybe we should only refer to them as "A human being......"

No, that would upset any aliens reading the thread!!!!

Anyway, I am not sure that some people would qualify as human these days.

I am offended

-

1

1

-

2

2

-

-

It looks as though the covering is pre printed Toto

-

-

Try helifreak website

-

Check on e-bay I found a site that sells fuss shells from China nut cheap though all uk suppliers show out of stock

-

lovely work David its a pleasure to follow this build

-

On 12/04/2023 at 12:05, Geoff S said:

Alas, I am one of those pedants 😞 In other words, I'm revolting.

how can we judge without your picture 😉

-

1

1

-

Warbirds Replicas Hawker Tempest V -Mass Build 2024(part two) .

in Warbird kits

Posted

Your right dear I'll start keeping some in the house