Rob Dunn

-

Posts

172 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Rob Dunn

-

-

Hi Geoff,

Do you have an update.

-

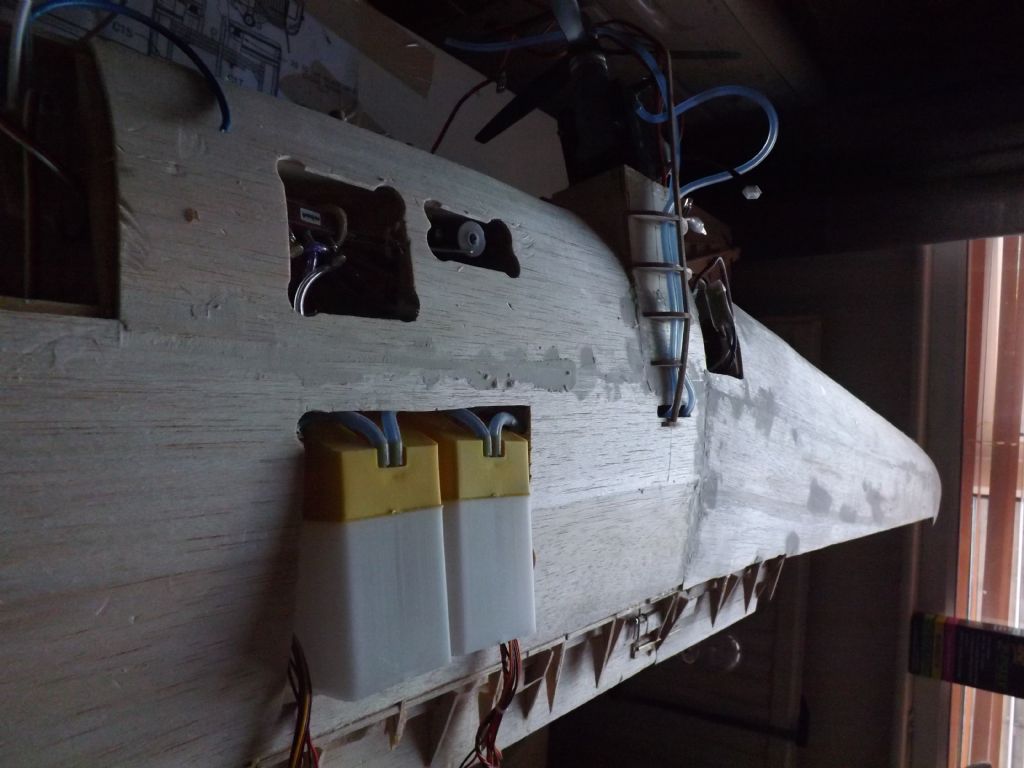

Been awhile since the last update, the build is almost complete all wooden parts are glued in all cracks filled and all working parts added and setup.

Been awhile since the last update, the build is almost complete all wooden parts are glued in all cracks filled and all working parts added and setup.Still to do

have to purchase 2 new switches as remembered had some dubro switch stations which i will use, receiver to be mounted in its final place the canopy and rear hatch will be removeable when required am going to blend them in with filler and covering then all it will take is a hack saw or scaple to remove. Then a final sand, fuel proofing and covering,

have to purchase 2 new switches as remembered had some dubro switch stations which i will use, receiver to be mounted in its final place the canopy and rear hatch will be removeable when required am going to blend them in with filler and covering then all it will take is a hack saw or scaple to remove. Then a final sand, fuel proofing and covering, -

Hi for electric setup I can not help you as I am building the TF DC3 using 2 x ASP .46 2 stroke with 10x6 3 blade prop's

Rob

-

The wing is final shinned and loads of filler used

wing tips on and ruff sanded ailerons built and fitted just need to get the fine sander going landing lights still need to have a cover mage have some clear plastic thinking about using a plastic bottle as they are thin.

wing tips on and ruff sanded ailerons built and fitted just need to get the fine sander going landing lights still need to have a cover mage have some clear plastic thinking about using a plastic bottle as they are thin.undercarriage all fitted and works

now on to the nacelles and cowling need to get some automotive filler of some sort

now on to the nacelles and cowling need to get some automotive filler of some sorthave made some 1/16th ply hatches for the on-board glow so I can have access to them need to sort out the charging socket for the battery

-

-

Have not been up to much on the build been routing the wires and plumbing. Flaps are complete and fit ok some minor adjustments required which will be done when the servos are connected.

Due to the amount of connectors I have used ashlock connectors which will house the Ailerons , Flaps and throttle

which leaves the retracts and lights so instead of 8 connectors only have 4

fitted 4-max landing lights which have an of on switch so this can be connected to a channel and used when required and power is supplied by a 2s lipo the receiver battery is not used.

Have not been up to much on the build been routing the wires and plumbing. Flaps are complete and fit ok some minor adjustments required which will be done when the servos are connected.

Have not been up to much on the build been routing the wires and plumbing. Flaps are complete and fit ok some minor adjustments required which will be done when the servos are connected.Due to the amount of connectors I have used ashlock connectors which will house the Ailerons , Flaps and throttle

which leaves the retracts and lights so instead of 8 connectors only have 4

fitted 4-max landing lights which have an of on switch so this can be connected to a channel and used when required and power is supplied by a 2s lipo the receiver battery is not used.

-

-

Thanks all,

Yes the kit is well laid out and fits together quickly, Have a lot of sanding still to be done and this will take up a lot of time. BEB the covering in some areas is 1.6mm due to the complex curves at the tail end if you are not careful like myself who is a bit heavy handed all sorts of things happen. The main sheets are 3/32 due to sanding some areas do come thin and you only fine them when your finger goes through.

Now the working parts are starting to go in I will be slowing down as need to work out the wire and air routes.

-

Looking absolutely stunning well done

-

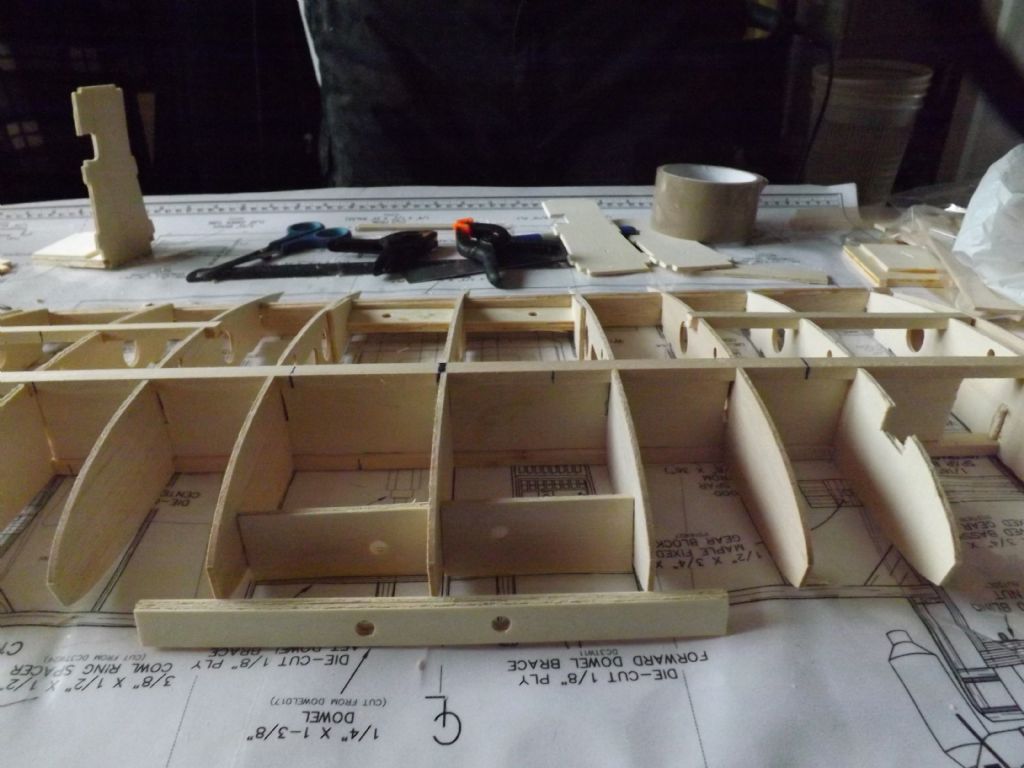

Been busy with the wings a lot of dry fitting and sanding then measure recorrect then measure again does not help when the wings are bigger than your table lucky the wife was out and the front room was free.

the outer wing panel are now glued to the center section

the engine nacelles are in place with the fire walls at the correct angle

the undercarriage has been fitted and tested need to remove for fuel proofing

first of two engine mounts on with engine fitted these have been temporary fitted as still need to fuel proof

one thing i have learnt is to mark the parts up or down left or right as this does help when finally glueing together lucky for 30min glue

-

-

-

Fuselage is final sheeted still alot of filling and sanding to be done, The balsa filler i have does not seem right maybe an old batch so have ordered some more different brand.

the rear hatch and canopy are removable the rear hatch will be held on by the covering as per instructions, the canopy i will be using magnets and a dowel to hold this on as the switches will be in the nose area.

When sanding need to be careful not to put your finger through the balsa skin as some areas can be thin.

Fuselage now been put to the side will waiting on the filler so been looking at the center wing section this is where you need to follow the instruction to the letter so have been busy rereading them over a cuppa will dry fitting the parts.

-

-

-

Been away for a bit suffer with the back, Final managed to finish's of the fusealge skinning a lot of sanding at the aft end. rudder and elevator push rods are in place and connected to the tail wheel, will be doing the removeable rear hatch so i can check on the clevis will be changing the clevis to metal instead of the plastic one's As long as you follow the instructions you can not go wrong take each step slowly. Balsa filler is now drying then just a quick sand to shape. Need to make the canopy removable as this is where the batteries will be going to use magnets to hold down the canopy.

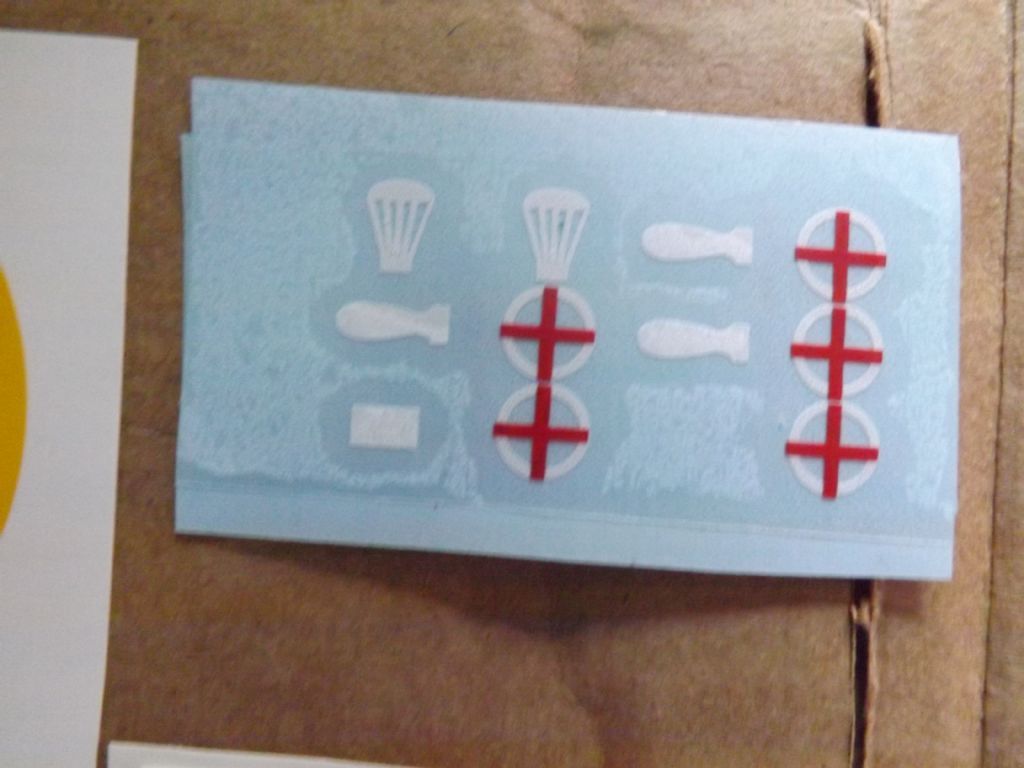

Big thank you to Pyramid models for the decals of the Reg number, Mission symbols and aircraft name

-

-

-

Thats a very good idea Andy something to think about

-

Only done a small amount of work over the past 2 days was out flying yesterday couldn't stay in with the sun shining and very little wind.

Only done a small amount of work over the past 2 days was out flying yesterday couldn't stay in with the sun shining and very little wind.The stag and fin are now glued in place i must of spent at least an hour or two thinking about doing this the nerves where higher that a someone on drugs. With a bit of sanding some tape and a square, Following the instructions all worked out just fine

Made some school boy error's with the balsa skins , with some filler and abit of sanding it will all work out just fine, He hopes

-

Thanks for the advice steve,

I have decide to buy the 3m mask and another with replaceable filters to see which one i prefer, The one i dont like will do to the father as he is restoring an MGB GT so will not go th waste.

Mowerman didn't i see you in a Batman film

-

Thanks Trevor, The booklet has some very good tips and ways of building, i am enjoying the build nice to just sit down a let the time go by

-

thanks for the repies will look at a mask with replacable filters in stead of the throw away types after one use.

-

I am getting into building from plans and kits and wondering what dusks mask members use and advice on getting one as I have noticed I am starting to suffers from the dust when sanding even when outside.

1/4 Scale Twin Turbine A10

in Build Blogs and Kit Reviews

Posted

Sorry to hear, Give my best to him.