-

Posts

3,392 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by Chris Walby

-

-

I hear Jon is on holiday, best be British about it and wait for his return.

-

Thanks guys for the kind comments although it was made a lot easier with everyone else's advice.

Danny,

I'll leave the C of G where it is and get a few more flights in first as there was a comment about ailerons and yaw that I might have a play with in flight modes.

The other thing was how benign the landing was (yes I came in fast), but as the speed bled off there seemed plenty of elevator authority all the way down.

PS as winter sets in just watch out for the poor light...I find matt camouflage and big circuits a particular challenge.

-

-

-

No more excuses maiden day.

Can’t say I really enjoy flying from this end of the field (trees look closer), but wind direction was directly along and I had a couple of aborted cross wind landing with the Dual Ace prior to flying the mossie!

And onto the Mosquito maiden

Into 10mph head wind with gradual increase to ¾ throttle aircraft accelerated on very short grass promptly, but not with the urgency of the Dual Ace (the mossie is 2.5kg heavier). I edged the throttle up a bit more and fed in a little elevator with the resulting gentle climb out, with no detectable swing.

Balance seem good with no elevator trim required and throttle returned to ¾ and expected increased in speed and height. Aileron response was okay, not too much, but might not be sufficient for a less that scale roll and very good distance sight.

Did a few circuits at various power settings with the observation that below ½ throttle its was noticeably more difficult to maintain height and speed. Turns at less than ¾ throttle seemed to wash speed off.

Landing, gear down, no noticeable change in pitch (was cross/down wind so not easy to see). Flaps ½ resulted in no appreciable pitch up however after my down wind runs with gear down and flaps ½ and a quite tight (still scale) turn in I ran out of aileron travel. One poorly lined up landing run resulting in power up and go around (not snapped open, but no appreciable yaw). Second attempt landing with no flap was more comfortable and head wind was closer to 15mph. Very smooth decent with throttle resulting in gentle flare that was surprisingly long. I was expecting the weight to have greater affect like the Dual Ace where you hold it off the ground and then plops down as the wing stalls. This seemed far more progressive.

Ran into longer grass, but did not nose over.

Conclusion, first ever time flying a 7.5kg model and it was very pleasant with little vices if the speed is kept up. Best flown at ¾ throttle although with flaps ½ or full (30 degrees) it will go quite slow I expect, but might have a nasty sting!)

Comments from club members

-

Seemed a little nose heavy flight

-

Take off from the club house looked prompt/quick

-

Sounded so good with the two lasers very slightly out of synchronisation!

Jon, thanks for your assistance throughout the build + all the other Mossie owners who chipped in with valuable advice. Lastly to club members for encouragement, words of wisdom and assistance, oh an a hole load of micky taking!

Photos and video to follow.

-

-

Dirk, Superb looking model and all the best for the maiden, even worth a double post!

-

Chris,

Thanks for the very informative descriptions of flight and ground performance its very useful to know what its likely to do and be prepared. I had not fully considered the substantial swing as the Dual Ace is totally benign even if I slam the throttles wide open (ground runs only, as I follow manufactures recommendation and take off on 3/4 throttle).

I have a couple of warbirds that swing although rudder deals with it adequately and the pits fence will prevent any off runway excursion on a northerly take off.

I hope you resolve your inverted running issue, what do you think the problem is?

-

Blustery afternoon at the flying field with a few of the hardened pros enjoying the conditions. For me it was have another go at setting the engines up now I have them on separate channels.

I was scratching my head until Dave helped out (well took over!) and in no time we had full and tick over set up on both engines.

Following more tea we conducted the noise test with it passing nicely. Must be those 13 x 8 blades that make the difference!

Few minor mods and double check everything and I'll be ready to maiden...I know this is over thinking it but it only has 10% more wing area compared with 25% more weight for two aircraft both powered by Laser 70's

On the plus side the Mossie wing is about 25% thicker wing and the engines are not trimmed back to get through the noise test (It was darn windy doing the 4 point noise test!).

I'll post some photos once the decals are on.

-

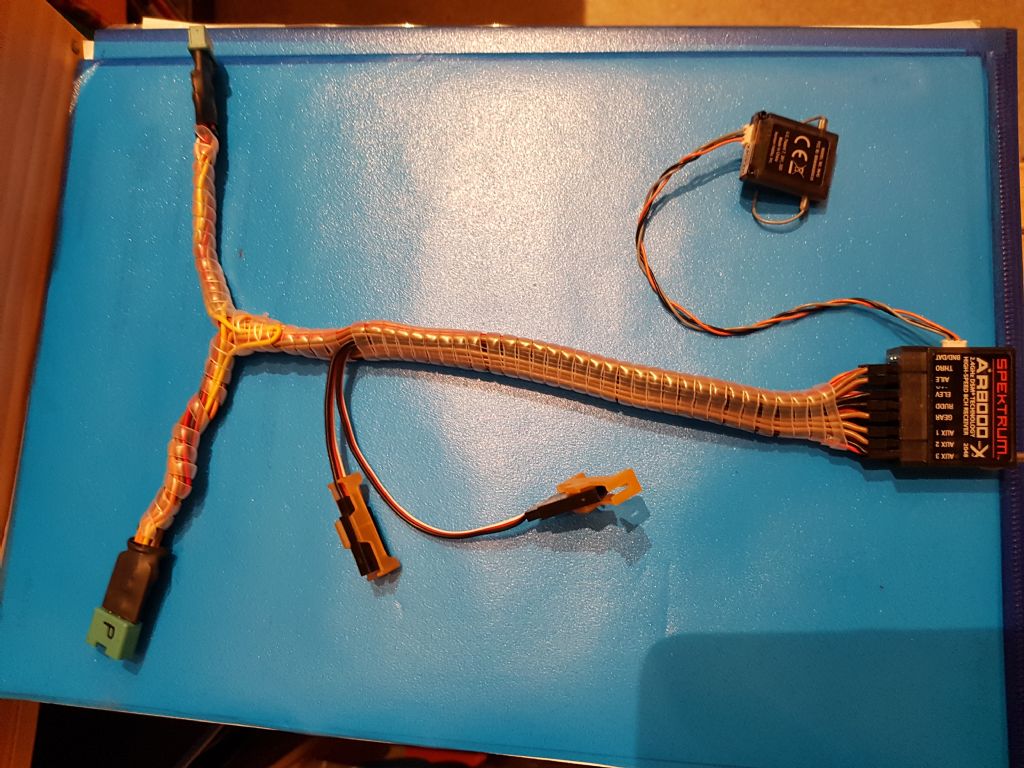

Still making progress here as the weather is not so good and work in very busy, anyway wiring loom finished and tested with the new plugs + 8th channel used for the other throttle output.

And the pilot close to being finished

Need to head back up the field for more checks and the noise test on Saturday.

-

Ron's answered the question regarding matt...is it mostly fuel proof?

-

Gary,

Do you have to set it straight or slightly more so it can relax back? Then go around the complete wing and make sure all the glue joints are okay.

Then get the covering back on, must say you do like a challenge

-

Hi Jon,

I see where you are coming from and I had no trouble with the new twins in the Dual Ace as the rods are accessible and have a clevis on the servo arm.

I have made a rod for my own back (no pun intended) by going with the Seagull (thin rod, tube and barrel on the servo arm. As I have committed to new plugs/sockets on the wiring loom + sorted the additional throttle channel in the TX out, I might as well do it all now.

The alternative is replacing the throttle rod and I really can't be arsed with taking the cowls off and engines out to do it (not if I can do it with a couple of soldered wires).

I spent Sunday up at the field and they are real close, but its a fiddle lifting a seven and a half kilo model onto the bench upside down and adjusting the barrel grub screw.

I did the gear on separate channels and it was a doddle to set them up with different end points on the TX (still don't like mechanical retracts, but these are nice).

-

Ronos,

Nice mod with the tank (wish I had taken the plunge and removed that much of the box) although my bulkhead is further back/throttle linkage passes through the void.

General update:

- Pilot painting has been subcontracted to my daughter with a more artistic touch than me

- Wing fixing ply washers to me made and installed

- Bought a new RX to resolve the range issue (Spektrum/Lemon thread if interested)

- Wiring loom

Personally (with myself) I have a problem with a using JT-XH connectors after a comment about my "miss use" of them. I thought the comment was inappropriately harsh in its bluntness, however following some testing I have found issues with them.

This coupled with the aggravation of setting the engines up by adjusting the grub screw on the servo for each one, I have to pick it up off the ground and invert it on the bench then fiddle about.

I have ordered some recommended 6 pin connectors, will have to use servo connectors for the wing lights.

Good news is I have almost cracked the dual throttle channels, throttle cut, failsafe issue so will use the 8th channel and have independent throttles I can trim on the TX (yes I know others suggested it and now I know why when the linkage is so hard to get to!).

-

Gary, Just being a bit dense here so bear with me. Is one wing warped with a twist in it or does the tip sit higher than the other side (like added dihedral)?

If its twist can't you set the middle of the wing straight (then the tip will be up and the root down by the same amount) by adjusting the wing bolt locations. Knowing Seagull you will need to re-glue every joint in the wing if you get it to move!

If its got a bit more "dihedral" than the other side then it will be a bit more tricky unless you off set the wing tube I the fuselage!

I know the above does not address the issue directly, but it might get it to fly in a reasonable way.

-

Most likely unrelated, but I was playing around with my lowly DX8g1 and mixes when I had the same sort of issue. I had reduced the travel on one of the aux channels which produced the effect where the channels would not follow each other.

Hope that helps

-

Ken, Are yes the import tax/vat and the hefty charge for the postie to deal with it....My fee was slightly less, but only because the goods were about ten quid!

Chris....ne...1... even more stung!

PS live and learn

-

Ronos,

I'll weigh mine again and see what it comes out like (not that its flow yet) although reading here and other places I don't think there is a light one out there (especially IC). If its a little overweight it will just fly a bit faster (okay the stall speed will be higher as it won't actually fly faster... yes yes I know they ballast gliders, but that's off topic).

I can't see the point of adding lead if the RX lipo is mounted in the tail! but once you have done what you can then lead it is to get the C of G.

As mentioned earlier up to 7.5 Kg no real issue, over 8 Kg then a diet would benefit it, There is an advantage of increased mass and that is better penetration in windier conditions...aarrr back to glider ballast again.

Off to the shed with the kitchen scales

-

All confusing stuff, could just give George a call at 4-Max discuss what you want to do and I am sue he could recommend a motor, esc and prop set up to suit your specific requirements (3S)

Just depends on how much time you want to spend working out what you need or up at the flying field.

-

Thanks Danny, I had the same idea and will shorten the bolts up at the same time.

I tried some Vaseline and one is still very very tight. It looks quite a course thread so I don't think its metric. The one on my other Seagull is a UNC if I remember correctly (I used some bolts out of my dad's collection of BSF, Wit, UNC and UNF) ! Its not very time efficient searching through loads of old marmalade tins where the masking tape has faded beyond recognition, but I do find the odd gem where it shouldn't be!

Photo below won't post last night (technical issue), but as you can see its getting close!

Edited By Chris Walby on 01/09/2018 07:29:46

-

More progress today with the engine and tank install complete + a load of the little bits and bobs.

Up to the field for a check over, C of G and engine run up.

I still have the pilot to finish painting, but the C of G comes out at 130mm wheels up and very little chage with wheels down.

So very happy with this

Less happy with my RX issue and my inability to set the throttles up the same...but at least both engines ran up with no issues.

Couple of questions for the other owners

- Mine seems to have a lot of fore and aft movement between the wing and fuselage and looking at the wing bolts the inner fuselage flexes an fair bit

- Does anyone know what the thread is for the wing bolts and I need to tap a tight one out?

-

-

Related question...once they have been attached do people leave as is (even IC glow powered models) or do you coat the entire aircraft?

Callie recommends a "clear coat" and I was wondering from the experienced forum members what they have used to achieve a matt finish.

PS I can brush or spay if necessary.

-

I am trying out JST-XH balance lead connectors, current model is using the 7 pin version for:

- Positive

- Throttle signal

- Aileron signal

- Flap signal

- Gear signal

- Wing lights (+3v)

- Negative

The additional advantage of making a loom up with male connector for port and female for starboard is that the gear (and others if needed) can be on different RX channels.

I use standard heavy duty servo leads from the RX to where the leads split Port and Starboard and then solder the connections to the JST-XH plug/sockets. The positive and negative are respectively combined so plenty of current available or you could connect directly and avoid servo supplies going through the RX, handy if you want retracts on a different supply.

Edited By Chris Walby on 31/08/2018 08:08:34

-

David,

The DX8 g1 does almost everything I need (apart from two throttles both with throttle cut (which almost works!)).

What I can't quite see is why pay another £100 pound more for a DX9 compared with a DX8 g2?

I have tried telemetry but its a faff to move between aircraft (and does no tell me much with a DX8g1 unless you are looking at the screen!) and now I am heading IC its not so important! ...Its gone quite..must be a dead stick!

I'll keep my son's DX8 g1 for the DSM2 RX's and resolve the Lemon 10 channel RX issue with a DX8 g2. The alternative is to only buy Spektrum RX's (after buying two or three I could gave bought a DX8 g2 and have a nice shiny new TX).

Peter,

I am happy with the DX8's I have, only one other problem in 1210 flights over 4 years (excluding the other Lemon 10 channel RX which displays the same issue).

So to finish off, what's the difference between a DX8 g2 and a DX9 that justifies £100 (if I don't need the 9th channel)?

Powered by Laser, a gallery thread

in Photography

Posted

See Seagull Mosquito Laser thread for details, but here it is before the decals were put on and the maiden.

If you have a pair of 70's then best put them in the "Wooden Wonder"