-

Posts

3,613 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Calendar

Downloads

Posts posted by EarlyBird

-

-

Please stop cracking jokes, my side hurts when I laugh. Which does not happen often.

Well it never happened until I joined this forum, a good tonic you are as well.

Thanks for being here.

Have you ever heard of HMAC because I think I met you there. Cold be a false memory of course.

-

How would a garden Mole have anything to do with a leak in the bathroom?

Is this Yorkshire humour?

No chance of a Lincolnshire Yellow Belly understanding Yorkshire humour.

-

Mole DD?

-

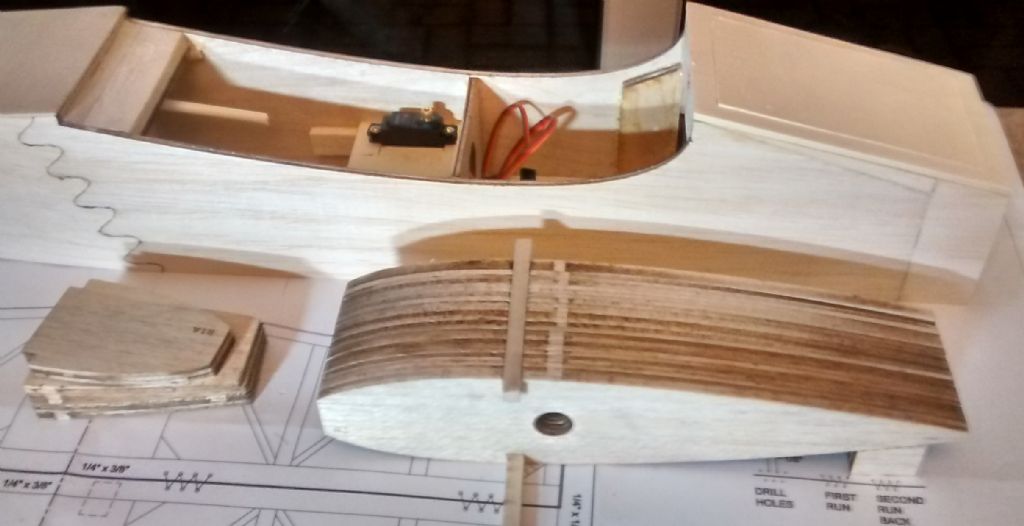

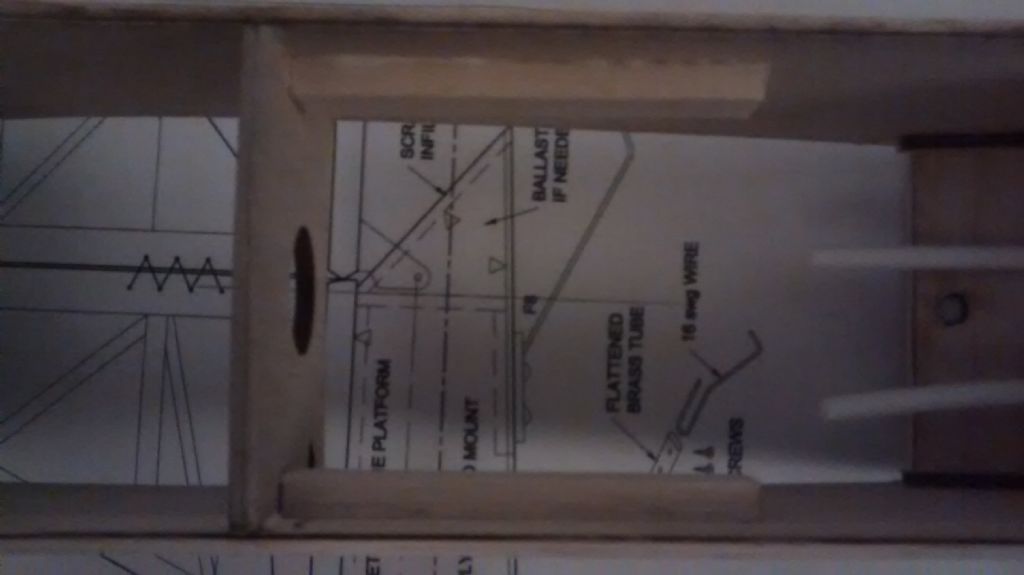

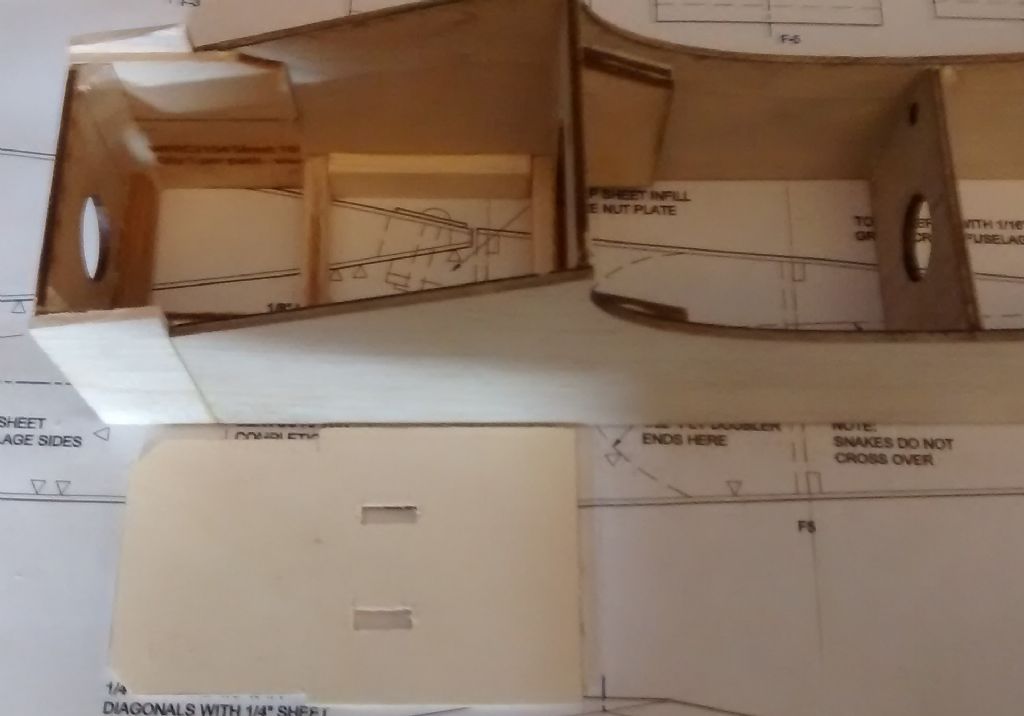

Snakes and servo tray glued in.

Ribs test fitted the spars which required the slots to be filed down to fit. Then sanded to remove the laser charring.

Bottom fuselage sheeting was not fitted today because I had to find a plumber to repair a leak in the bathroom.

The good news is that the order I placed on Sunday was delivered today, well done SLEC, I now have all the balsa I need.

I have decided not to make any promises about what I will do tomorrow that way there will be no more leaks.

Cheers

Steve

-

-

Yes, that is what the manual says.

-

Press the < button to put it in manual mode. This will make it permanently on. When you want it back in Auto press the > button. there is a indicator arrow on the screen to tell you which mode it is in.

-

-

-

-

Thanks Martin.

I am calling it a day!

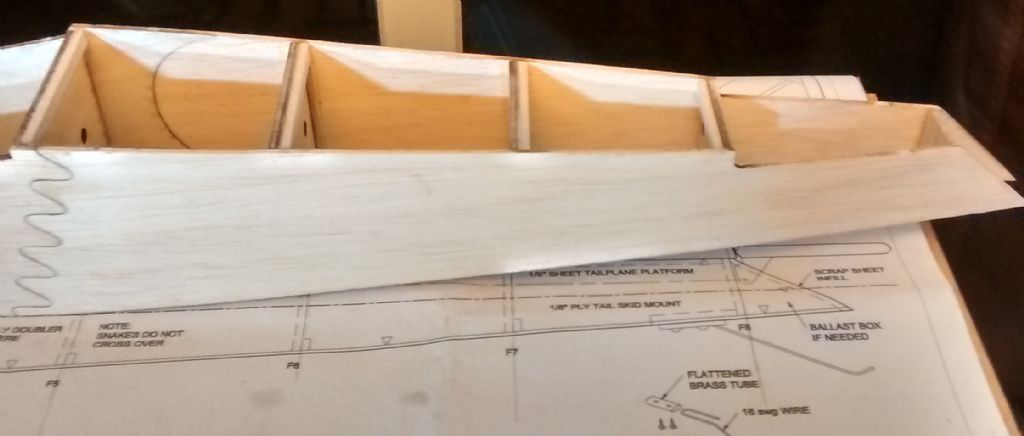

What's left to do on the fuselage? servos to fit, tail skid plate and bottom sheeting then on to the tails surfaces and wings.

This has to be the easiest build ever. The wings are flat and built in one piece as you can see the fuselage is a box, no cowl and no canopy.

More fun tomorrow.

Cheers

Steve

-

The fun continues this morning!

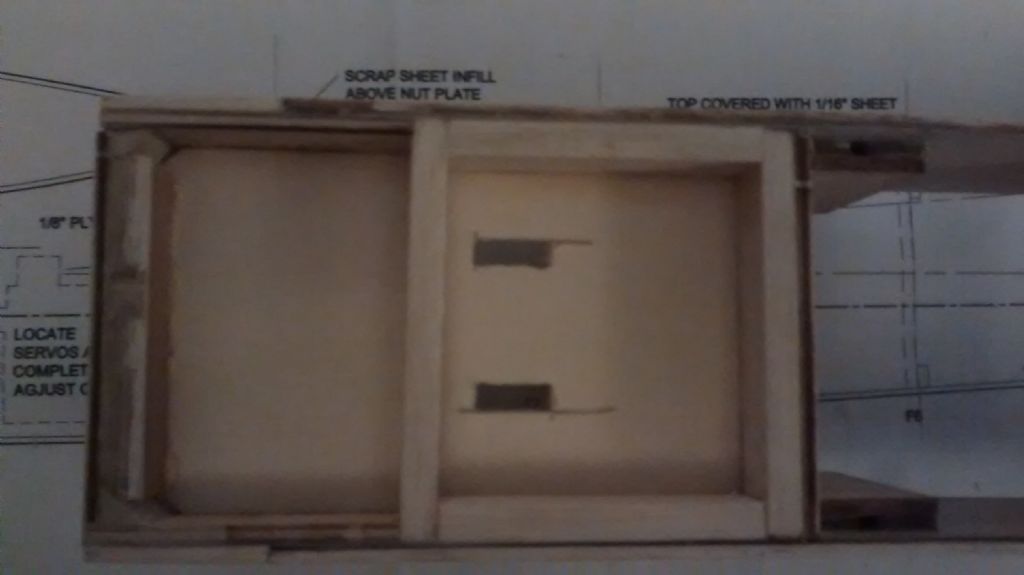

Hatch frame glued and sanded to fit the fuselage,

Snakes installed and top deck glued in place.

This is quick and easy!

It will not be ready for me to fly on Christmas day though

I will just have to fly my HK Crusader and my really old 50" stik, early 90s is my guess. I bought it second hand for my son to fly from my LMS Shermans, long gone as are so many others

.

.Cheers

Steve

-

All good advice KC and Peter.

More bits glued on.

Wing bolt plate and scrap balsa sanded to shape.

Bottom plate for the undercarriage and hatch boxed out ready for ply frame.

Ply frame cut out ready for glue.

With hatch test fitted.

I will glue that tomorrow after some final checks and trimming no doubt.

What's left to do on the fuselage?

Servo mounting, snakes and decking hmm

anything else.

anything else.Today I ordered a jig from SLEC that will be used for the first time on The Ohmen fuselage

along with hard balsa spars, hard balsa they do have, well in the sizes I wanted.

When that comes I can start the wings unless I use 1/4x1/8 spruce. Another decision to be made.

Another good fun filled day

Cheers

Steve

-

-

An interesting project Dave.

It looks like you are using lite ply, lack of balsa?

Design changes add to the fun IMHO and scaling up even more so. I have yet to advance to scaling up and plan building but it will happen.

Cheers

Steve

-

Hinges

as it happens I want to try covering film hinges and magnets. My thoughts now are to use lite ply hinged at the front with magnets to hold it in place.

as it happens I want to try covering film hinges and magnets. My thoughts now are to use lite ply hinged at the front with magnets to hold it in place.If I cut the ply to the width of the fuselage and to the length from F1 to F2 then cut out the centre to leave a frame which will be glued in place and the centre will be the hinged hatch.

I will give it a go. Nothing ventured nothing gained.

I will give it a go. Nothing ventured nothing gained. This designing lark is fun!

I love Skylarks.

Cheers

Steve

-

-

-

-

-

well done you two!

well done you two!Or did you do something wrong?

-

-

KC 1 1/4" as you said 32mm in my money. That looks fine to me but time will tell.

Pictures to follow.

Cheers

Steve

-

Swizzle Stick

in Peter Miller plan builders

Posted

Hibaldstow Model Aero Club

I am sure I made you a cup of tea.

Must have dreamt it I guess.