-

Posts

2,070 -

Joined

-

Last visited

-

Days Won

30

RICHARD WILLS last won the day on June 27

RICHARD WILLS had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

RICHARD WILLS's Achievements

2.3k

Reputation

-

Yes Ron , he bought the first pair in a size too large...........😕

-

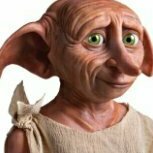

The Geordie Lad actually popped into Wiltshire today to let me fly the new Me109e prototype . Apparently he has taken to wearing two hats . This , he explained,is because the larger hat doesnt actually fit and ends up dropping down over his face . So he wears a smaller hat under the large hat . I pointed out that if everyone adopted this stance , we could all be wearing two or more sets of clothes . Why not just buy stuff that fitted in the first place ? Anyway , despite this millinery perversion he had made a very good job of the model . Needs a few cosmetic additions to be "Fit to Kit " ,but flies very nicely with benign stall and sprightly performance . Outside of Knotty Ash and the Treacle Mines , I don't think multiple hat wearing is going to become a thing 😬

-

A bigger foamboard build - Miles Hawk Speed Six

RICHARD WILLS replied to Lipo Man's topic in Own Design Project Blogs

Yes , go for the first drawing as the second angle will punch the spar too hard if you hit a pot hole . As you say , to keep it simple put all the forces through the spar . So rather than create a separate block mount for the torsion bar and anchor point , why not face the spar webbing from top top to bottom with marine ply . About 5" long will do the job . The wire will run along the bottom in saddle clamps then go vertical at the inner end to act as the anchor . (as shown in Eric's last picture) . Make the vertical full depth of the wing though . -

A bigger foamboard build - Miles Hawk Speed Six

RICHARD WILLS replied to Lipo Man's topic in Own Design Project Blogs

LM , lets keep it simple . Looking at you r first drawing , you are nearly there . The impact on landing gear is mostly back rather than up . With the wing loading you will have , up shock will be minimal , so forget the lower coil. However , as Eric says , any bracing behind the leg will be a problem . It will either break the brace or damage something else . Set it up like a low wing sport model where the undercarriage wire turns to run along the wing span wise for a few inches before being anchored . That will allow the impact to be absorbed like an anti roll bar on your car . The next problem , is what to do about the Spats being damaged by the rotating (under impact ) legs . I think that with the slowish landings expected , the rearward twist will be modest on most arrivals ,especially with your forward kink . Perhaps make the spats a little larger at the back to allow more swing and retain them at the top with magnets attached to an inner former at the top. -

A quick update on the Mossie . Converting the half foam board model into a wooden kit had concerned me in a number of ways . Firstly , could the weight be kept similar (particularly at the back end ) in order that a 64" model could balance with just one 3300 4s battery ? Secondly , the joint separation behind the wing being easy be structurally sound . Thirdly , with the upswept rear fuselage meaning that my usual central crutch would not be horizontal , how did I mount the tail assembly firmly ? On the mock up shown below you can see that the tail has a long overlap onto the crutch and is at the same time , sandwiched by the foam decks making it nice and stable . The fuselage joint is nice with the radio aerial being extended through the model to pin it in place . There will be a magnet at the bottom of the aerial tube , so no screws or fasteners to lose at the field . The best result is that even with one pack and no props it balances pretty much on the money . Also note the little tail moulding which saves both work and weight at the rear end (well done Paul ) Out of interest , we found the quickest route was for me to make a wooden one , send it to Paul who then creates the same in 3D for a male mould . It compares well with the foam board variant in the last shot .

-

A bigger foamboard build - Miles Hawk Speed Six

RICHARD WILLS replied to Lipo Man's topic in Own Design Project Blogs

Looks great so far LM . U/c mount is your next challenge 😬 Is that a Braeburn , or Cox's Pippin ? -

Warbirds Replicas Focke-Wulf 190 Build Log

RICHARD WILLS replied to Gordon McConnell's topic in The 2024 Forum Mass Build

Ive been away Gordon , so missed the pictures. Your 190 looks fabulous (so does your grass!) I dont worry too much about the underside of my models . Ive never had anyone pick one up off the grass and inspect it .😬 I particularly like the choice of colours on yours . Can you fill us all in so that others might copy ? Richard -

I think motion Rc has a deal with him . Have a little shufti.

-

Yes , Paul and I both use the Mr Rc sound systems . The new Spitfire and Mossie will have a space set aside for the speaker .

-

no list yet chaps so dont panic , we never leave a man behind ! but comments welcome (and questions)

-

Beware the Hun in sun . Tally Ho chaps!

-

The Mosquito is still progressing so lets not panic about that . It is complicated for me in order that it is way less complicated for you . It wont be for everyone though . So lets have a look at what else might be on the menu in the near future . I have had a Spitfire design running since 1996 . In 2016 it really took a leap forward into the laser cut Mk IX . But I havent made any for quite a while as people seemed to lose interest , or had already built one . Its a shame because both Paul and Eric still have theirs and rate them very near the top of their "squadrons" . Its not to say we didnt tweak the design from 2016 , so it may be time to look at the most iconic of WW2 aircraft once again . If there were any negatives about the laser cut kit , it would be the bottom loading battery and the undercarriage fixing and geometry . Paul , with his obsessive attention to detail (I'm cowering slightly waiting for the left hook ) has persevered with the undercarriage and now has it absolutely spot on . All three of our Spits run straight as a die and do not nose over ! The experiments with resilience have also paid off and no longer to do we hear the "click of doom " when the undercarriage plate either cracks or detaches . Given the success of the Tempest/190 pairing last year (well over 100 so far ) , I felt that everyone was ready for the ultimate pairing . It has to be the battle of Britain early Spitfire and its nemesis the 109E . You have probably all seen the 109E flying prototype that Eric has been playing around with , so you can see that with some additional mouldings and details that the Luftwaffe option is nearly there . I am under no illusion that it will be the main draw . Ever since I were a lad , Ive heard experts tell me that Spitfires are difficult to fly . But now , after 35 years of doing my own designs, admittedly in the same zone of the club size Warbird, I feel equipped to deal with the "Big Issue" . That issue is that 95% of people that get into building scale models would ultimately like to build a Spitfire but have been warned off by other people or put off by other difficult to fly design . For me, the Tempest /190 adventure was rewarding in several ways . Because of the simple way we presented the kits here on this forum , several newbies had a go . We really need these chaps , so everyone should be as patient and helpful as possible because they ensure the continuation of our kits and the building hobby . Secondly , the Dollies (special thanks to all those that shared their own designs ) have been way better than I expected . They give people the chance to get into WW2 stuff without the initial complication of retracts , which can be a huge barrier . Lets face it , if you have say 50 flights on the 190 and have belly landed with ease every time , you will feel quite comfortable landing on wheels with the same "old friend". So, with all of that in mind , my intention is to create an early mark Spitfire which will be tough and light so that it can stand both belly landing and retracts . The build must be quick and straightforward for those with limited experience . (I sort of assess it by thinking , that if you have made a Chris Foss "Whatever" you can do this ) . I have switched back to a four piece foam veneer wing . They are tough, light and accurate . They also take retracts better than a built up wing . There will be a new top hatch for the battery . The tail has been tweaked to give a slightly leaner look at the back end . The wind shape is very accurate in plan form and also generates a lot of lift at low speeds which means it will stall very late and even when savagely provoked just does a lazy wing over . The model below lacks any detail yet but only weighs 5lb . Hand on heart , it handles beautifully . So the "Big Issue " I referred to is that I want people to say in reply to those who announce the infamous words "dont buy a Spitfire , loads of trouble " , "perhaps not , I fly mine every week " . As they said in the war , the peoples Spitfire 😉

-

A bigger foamboard build - Miles Hawk Speed Six

RICHARD WILLS replied to Lipo Man's topic in Own Design Project Blogs

I like your thinking LP . The Bearcat was a great result in that it was a big , impressive model, that was cheap and approached the finish line in a series of comfortable stages (ie building a flying box first ) Giving how cheap and available Foam Board is , It really is criminal not to "Go Large" . My only limitation would be , can it go in the car ? Having said that , producing in sections is also quite easy . I like the idea of large but cheap , so I would try to use two cheap batteries that I already have , rather than buy expensive 6 cell packs . But I'm sure you have already thought about that . https://www.youtube.com/watch?v=jGi-hFlzzNI -

I agree . I have never had a slow speed response from this site , but very lethargic at the moment . (not me , the site 😬)

.thumb.jpg.632415da66ae2d3b91c91514c153e5df.jpg)